When you need the most efficient and effective measurement devices for semiconductor tool set-up and maintenance processes, count on CyberOptics, the global market leader in wireless semiconductor measurement devices for chamber gapping, leveling, wafer handoff teaching, vibration, airborne particle, relative humidity and resistance measurement.

Semiconductor fabs and OEMs value the accuracy, precision and versatility of the WaferSense and ReticleSense measurement portfolio to enable improvements in fab yields and equipment uptime.

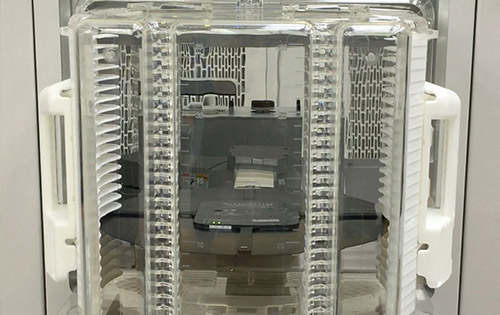

Since the wireless, Bluetooth® enabled and battery powered devices are wafer or reticle shaped, they can generally travel anywhere a wafer or reticle travels, providing optimal ease-of-use and access to locations that otherwise may be difficult or impossible to reach.

Calibrations can be done under closed-chamber process conditions with the vacuum compatible WaferSense and ReticleSense measurement devices.

Receive and record data in real-time on your laptop with CyberOptics easy-to-use software and count on accurate, precise, reliable and repeatable results that save time and expense compared to traditional or legacy methods.

CyberSpectrum is a powerful yet extremely simple software with an intuitive interface providing numerical and visual feedback for real-time measurement and analysis for multiple applications.

The WaferSense Software Development Kit provides the Application Programming Interface (API) to the WaferSense® and ReticleSense® family of devices. This allows direct integration of the device into user developed software applications.

NanoResolution MRS Sensor for Wafer-Level and Advanced Packaging Applications for OEM integration.