IPS™

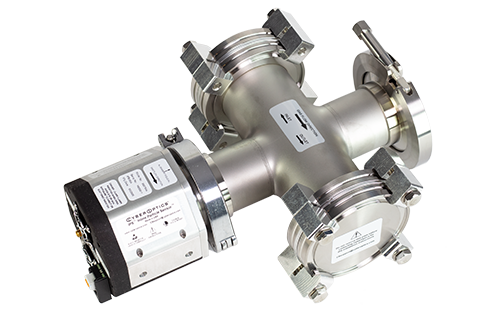

In-line Particle Sensor™ (IPS™)

24/7 detection of small particles in gas and vacuum lines.

24/7 detection of small particles in gas and vacuum lines.

Speed equipment qualification with real-time 24/7 monitoring.

Shorten equipment maintenance cycles with inline particle sensing.

Lower equipment expenses with objective and reproducible data.

Based on our WaferSense® Airborne Particle Sensor™ technology, IPS utilizes a high power blue laser to quickly monitor, identify and enable troubleshooting of particles down to 0.1µm within gas and vacuum line locations for process sensitive applications.

Mechanical Interface

ISO-63 flange (standard configuration)

Highly accurate

Measures particles greater than 0.1μm

Less than 5 false counts per hour

Vacuum Integrity

Less than 10-6 atm-l/sec leak rate

Laser

Certified to Laser Class 1