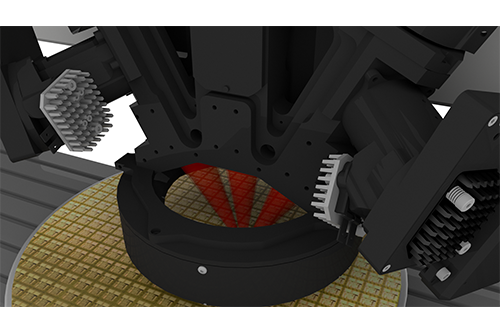

WX3000 3D and 2D metrology and inspection system provides the ultimate combination of high speed, high resolution and high accuracy for wafer-level and advanced packaging applications to improve yields and productivity. Powered by Multi-Reflection Suppression® (MRS®) Sensor Technology.

Metrology-Grade Accuracy with MRS® Technology

Fast, Superior Inspection Performance

Versatility for Wafer-Level and Advanced Packaging Applications

The 3-micron NanoResolution (X/Y resolution of 3

micron, Z resolution of 50 nanometer) MRS sensor

enables metrology grade accuracy with superior 100% 3D and 2D measurement performance for features as small as 25-micron.

100% 3D and 2D metrology and

inspection can be completed simultaneously at high

speed, versus an alternate, slow method that requires

two separate scans for 2D and 3D, and only a sampling

of a few die.

Delivering greater than 25 wafers (300mm) per hour for 12″ and 8″ wafer sizes and 55 wafers per hour (200mm) for 6″ and 8″ wafer sizes.

3D Capability

Full Wafer

3D Accuracy

0.2μm (VLSI standard)

3D Repeatability

0.3 µm @ 3σ (VLSI standard)

Bump Height (Size) Coverage Range

25-250 μm

3D + 2D Throughput (300mm full wafer)

≥ 25 WPH

3D + 2D Throughput (200mm full wafer)

≥ 55 WPH

2D Objectives and Resolution

Fixed resolution – 3μm

2D Measurement Accuracy for Bump & RDL

1/2 (1.5μm) pixel size accuracy

2D Measurement Repeatability

1.6μm @ 3σ

2D Measurement Range

>20μm

See brochures for additional specifications