ATS2

WaferSense® Auto Teaching System™ (ATS2)

Capture three dimensional offset data (x, y and z) to quickly teach wafer transfer positions.

Capture three dimensional offset data (x, y and z) to quickly teach wafer transfer positions.

Improve yields and lower particulate contamination with accurate wafer handoff calibration.

Achieve repeatable and reproducible semiconductor equipment setups.

Reduce equipment downtime from hours to minutes.

Speed trouble-shooting and lower consumable expense with visual inspection.

On-board image processor reports x-y-z offset from the teaching wafer to a target inside the equipment so you can teach wafer transfer coordinates.

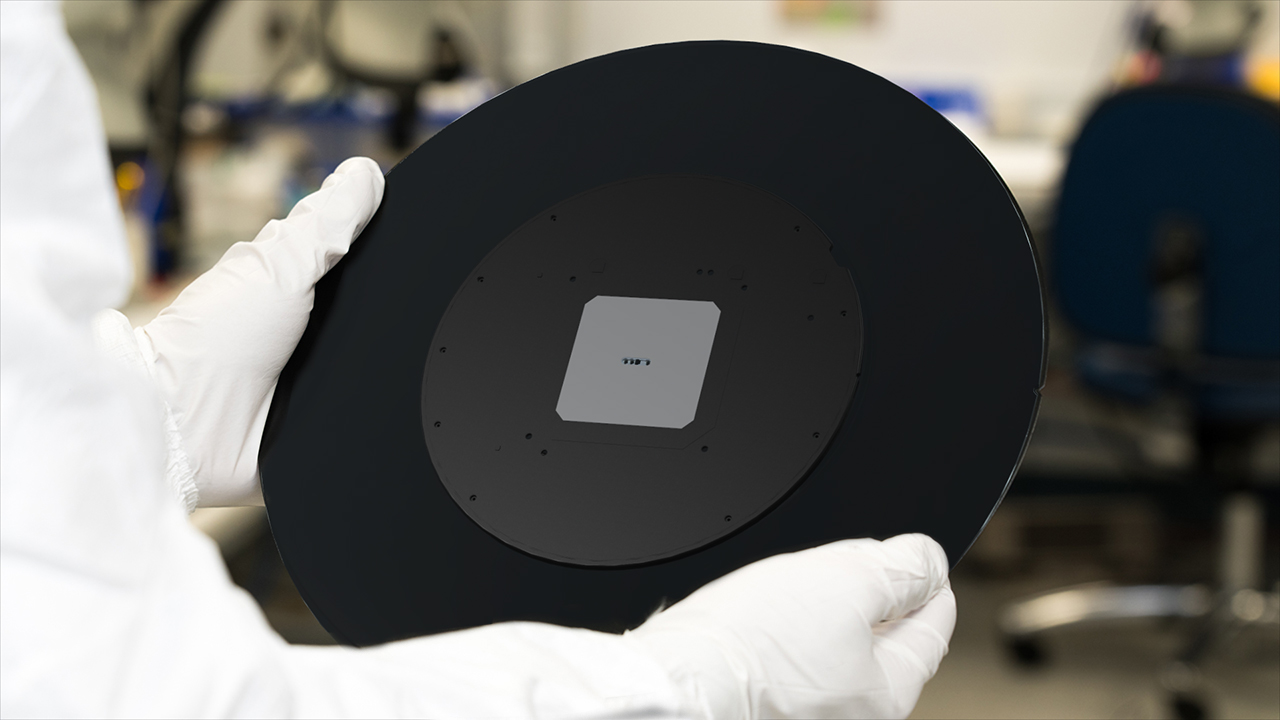

Wafer-shaped

Available in 200mm and 300mm wafer sizes.

Highly accurate

Accurate to +-0.1mm (+-0.004in) x and y position; +-0.8mm (+-0.03in) z position.

Wireless and vacuum compatible

Travels like a wafer and takes less time as equipment stays sealed during inspection. Transmits data in real-time.

Easy-to-use software

CyberSpectrum: Displays real-time video and measurements of target features, logs offsets and user comments. Allows teaching of circular features, 3mm-10mm diameter. Review functionality integrated; replays log file data for review and analysis.