ARS

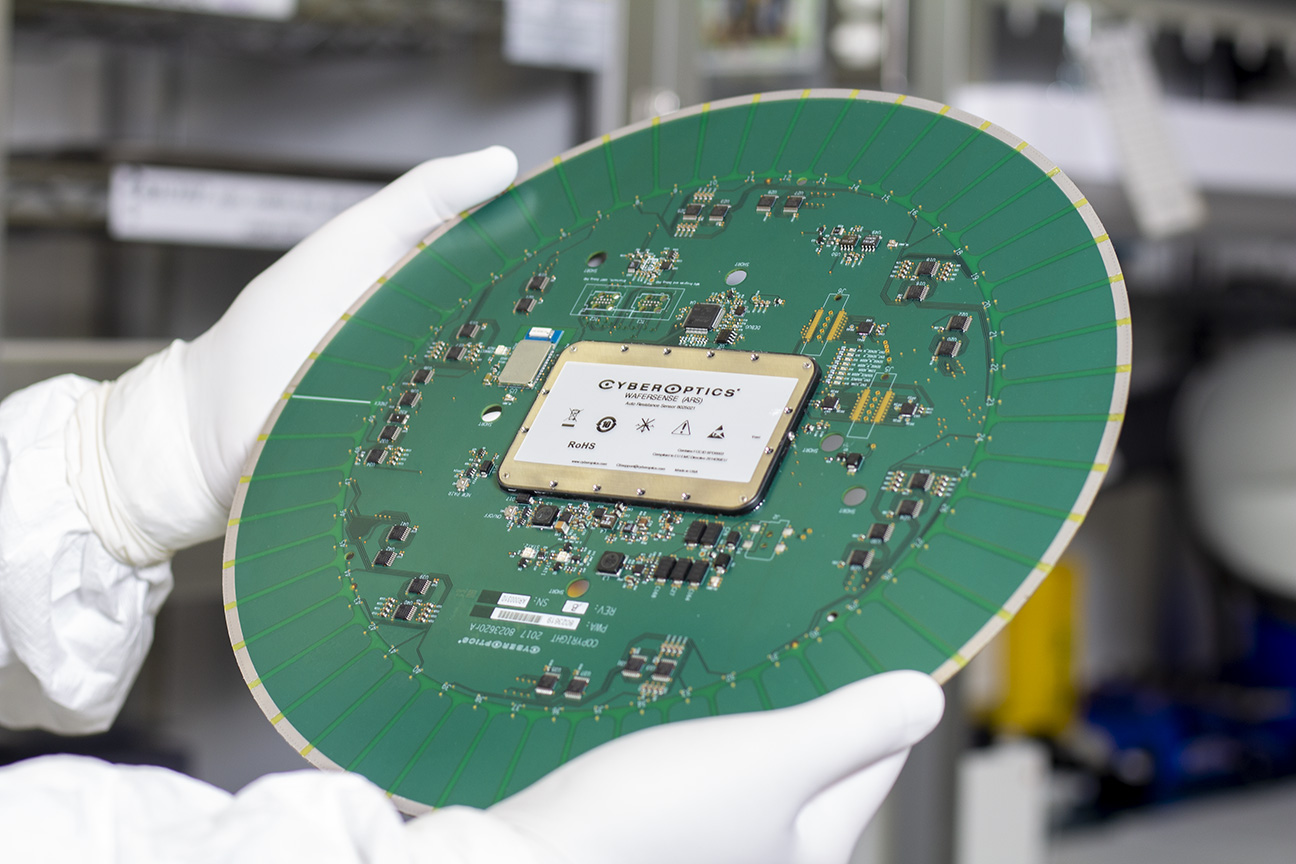

WaferSense® Auto Resistance Sensor™ (ARS)

Real time resistance measurement of plating cell contacts.

Real time resistance measurement of plating cell contacts.

Shorten equipment maintenance cycles with wafer-like 4-wire resistance sensor.

Predict when a tool needs maintenance with quantitative analysis of measured mean resistance over time.

Improve cell-to-cell process uniformity with objective and repeatable resistance measurement.

Quickly monitors and identifies resistance

measurements with 50 separate measurement pads around the perimeter, utilizing Kelvin

Sensing (4-wire resistance) method for accurate measurement of low value resistance.

Wireless, Wafer-Shaped

and Battery-Powered

Available in 300mm

Highly Accurate

1mΩ ±1% of range with normalized readings

Resolution of 100μΩ

Durable Housing

Edge contacts are mechanically robust with noble metal plating

50 Measurement Pads

Chemically compatible with SABRE chemistry and cleaning procedures

Lightweight and Thin

270 grams and 5.5mm thick