Benefit Summary

Flexibility tops the list of benefits as the SQ3000™ proves to be the most accurate and reliable solution for both AOI and SPI applications.

Challenge

Our customers were in search of a single solution that could handle both Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI). A flexible and robust system, would allow them to accurately and repeatedly measure both small, short components (~50um) and large, tall components (

The ability to manage both inspection cycles from one system would greatly reduce costs, training and operator time, and minimize the required footprint.

Solution

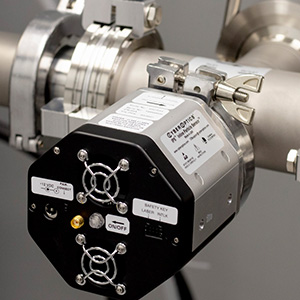

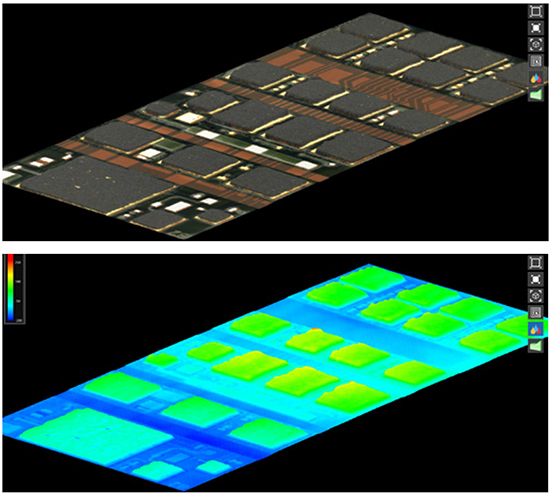

The SQ3000™ is the ideal inspection solution for these customers. This AOI system has the flexibility required for a variety of applications, including SPI. The sensor, software and system all work together to completely automate the full-line inspection process. With high precision, customers are able to utilize this solution without changing process and production based on layout for things like plot line design. The SQ3000™ offers repeatability of 6 micrometers in 3 sigma for X, Y, Z measurement.

The Multi-Reflection Suppression (MRS) technology offers a wide field of view to meet coverage needs for a variety of AOI and SPI applications. With this sensor, our customers are able to find defects sooner and mitigate any measurement inaccuracies due to variations and shine, reducing costs and operator time. Additional benefits of the SQ3000™ include ease of use, reduced training time and high yield inspection at fast speeds.

This proprietary system is a best-in-class solution that offers a remarkably low escape rate and continues to create operational efficiencies for our customers, helping them build trust with their customers.

Back

Back

Back to News

Back to News