SQ3000 3D Automated Optical Inspection (AOI) system maximizes ROI and line utilization with 3D multi-view sensors that enable fastest 3D inspection in the industry. SQ3000 incorporates Multi-Reflection Suppression® technology (MRS®) and highly sophisticated 3D algorithms offering microscopic image quality at production speeds. SQ3000-X offers expanded capabilities supporting large boards up to 710 x 610 mm, inspecting the most demanding assemblies without compromising measurement accuracy and repeatability.

Metrology Grade Accuracy

High Speed Inspection

Fast, Smart, Easy-to-use software

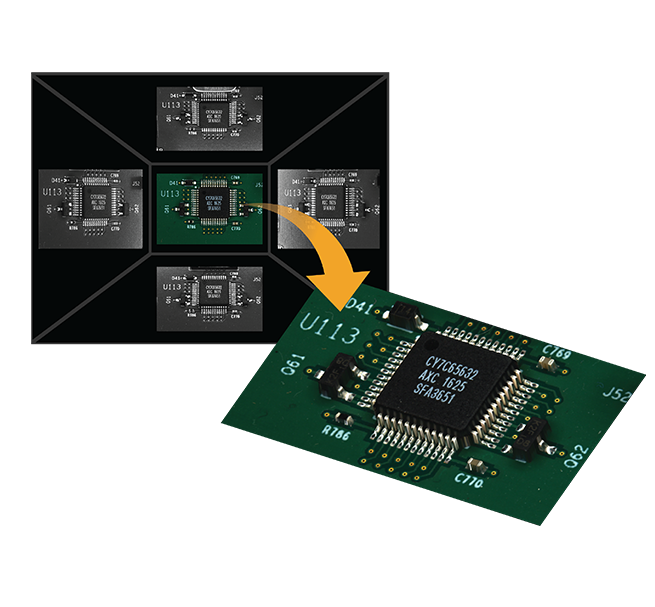

MRS technology suppresses any reflections that can distort the data, especially on shiny components, enabling precise 3D representation while the architecturally superior sensor design captures and transmits data simultaneously and in parallel. The result is unmatched speed and accuracy.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

Standard MRS Sensor: 40 cm²/sec (2D+3D)

High-Speed MRS Sensor: 50 cm²/sec (2D+3D)

High-Resolution MRS Sensor: 20 cm²/sec (2D+3D)

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D)

Field of View (FOV)

Standard MRS Sensor: 36 x 30 mm

High-Speed MRS Sensor: 36 x 36 mm

High-Resolution MRS Sensor: 26 x 26 mm

Ultra-High Resolution MRS Sensor: 21 x 21 mm

Board Size

SQ3000: Min. 50 x 50 mm, Max. 510 x 510 mm

SQ3000-X: Min. 50 x 120 mm, Max. 710 x 610 mm

Resolution

Standard MRS Sensor and High-Speed MRS Sensor: Sub 10µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 7µm

Component Height Clearance

Top: 50mm, Bottom: 30mm

Component Types Inspected

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

pins, and more

Component Defects

Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more

Solder Joint and Other Defects

Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins