Interview with Dylan Lundberg, Senior Manufacturing Engineer at Proto Labs

Q: What led Proto Labs to choose the CyberGage360 for its metrology lab?

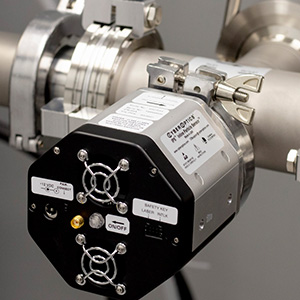

A: When we were looking at metrology options, we knew we needed something unconventional in order for it to align with the rest of our manufacturing process, focused on automation and speed. We envisioned some sort of magic box where we put in any given part and it turns into an inspection report. We didn’t know what existed out there in the marketplace, but that was our main philosophy of what we were trying to achieve. We have a stunning variety of unique parts that we need to potentially measure in a small amount of time. The CyberGage360 fits this need perfectly.

Q: What are the various parts that Proto Labs works with?

A: We manufacture prototypes and low-volume production parts using 3D printing, CNC machining and injection molding, so we see the absolute gamut of parts – from simple to complex geometries. The solution we needed for metrology was to be able to accurately scan all of these geometries. The CyberGage360 is able to do that.

“At Proto Labs, we strive to challenge the traditional rules of manufacturing in order to deliver custom-manufactured parts at unprecedented speeds. Everything we do revolves around reducing our customers’ time to market and we do that by digitizing the entire manufacturing process.”

– Dylan Lundberg, Senior Manufacturing Engineer, Protoworks

Q: What challenge were you trying to address?

A: We have tens of thousands of customers who depend on our quick-turn manufacturing services to machine, mold and 3D print custom parts every day. We often turn parts around in as fast as one day. In order to continue to do that, we need to be able to measure pretty quickly. Traditional ways of measurement just didn’t fit that scheme, plus the fact that we are a big proponent of keeping everything digital – everything else in our manufacturing facility maintains the digital thread. We don’t accept part prints, so with the CyberGage360 we can use product manufacturing information (PMI) data and keep everything digital to maintain the thread.

Q: What alternate solutions did you evaluate?

A: We considered all of the traditional ways like CMMs (coordinate measuring machines) and other traditional metrology equipment. None of it was fast enough for us. We needed a one-stop shop with ease of use, speed of use and accuracy.

Q: What process did you go through to test CyberGage360?

A: We work with so many different configurations and geometries, hole sizes, whatever it may be – just a lot of different configurations of parts that can fit into this window, so we tried to throw a wide range at the CyberGage 360 to test its capabilities, and what we found was that for the vast, vast majority of cases it was the solution we needed.

Q: How important will the CyberGage360 be to Proto Labs?

A: Metrology is extremely important to Proto Labs. Customers are demanding it. We needed a way to digitize inspection reports for our customers. The CyberGage360 is just the perfect synergistic solution that allows us to do this quickly and using the same scheme in which all of our other processes are done.

Q: What benefit does it bring to Proto Labs?

A: The CyberGage360 is fast. We needed metrology and we needed speed – the CyberGage360 gives us both.

Q: What benefits does it bring to Proto Labs customers?

A: There are enormous benefits for our customers. The key value we bring to our customers is the fact that we can turn parts around faster than any other manufacturer. When you couple that with inspection reports that can be done faster than any other inspection report in the world, you have this unrivaled combination for the customer that delivers both products quickly.

Proto Labs’ customers can now get digital inspection reports in the same or nearly the same lead-time they were getting their parts. It’s unprecedented when you look at the industry.

Q: What is the overall process flow at Proto Labs and how does the CyberGage360 fit in?

A: The CyberGage360 fits with our fast processes. We needed something that didn’t interrupt what we were already doing on the production floor. After a part is rapidly manufactured, that part then gets shipped immediately to our metrology lab and goes through the CyberGage360, which can generate an inspection report quickly too.

At Proto Labs, we’re firm believers in and committed to digital manufacturing. Our company is based on it and PMI is the next step of that. The product manufacturing information that can be put directly into the solid models completely eliminates any need for a drawing, even when you’re generating a metrology report – that’s where this

industry is going. The CyberGage360 allows our customers to put all of that information directly on to their model, similar to what they’re already doing today for us. They only need to send the Solidworks CAD model and we can take all of that information automatically, which means quickly, and generate reports and qualitative information based on it. The CyberGage360 allows the PMI data to be translated into exactly what the customer needs, and as quickly as possible.

Q: Proto Labs is highly committed to quality, can you tell me more about how important this is?

A: The key tenet of our quality policy is our commitment to delivering quality parts faster than anyone else, and meeting or exceeding our customer’s expectations every single time. The CyberGage360 has proven that it more than meets what we need as far as proving tolerances and proving dimensions for our customers.

Q: Can you tell me about the return on investment (ROI)?

A: When we’re talking about ROI for what we were putting into our metrology lab – we’re kind of unique, because we have a lot of change overs, we build a lot of different parts, so with the traditional equipment it’s a tougher sell because the set-up time kills us, but with this magic box – the CyberGage360 – it allows us to have essentially zero set-up time for these parts so we can get them done as quickly as possible without a lot of manual touching – so that’s huge. It’s a one-stop solution.

Summary

“At Proto Labs, we strive to challenge the traditional rules of manufacturing in order to deliver custom-manufactured parts at unprecedented speeds,” said Dylan Lundberg, Senior Manufacturing Engineer of Protoworks, Proto Labs’ R&D lab. “Everything we do revolves around reducing our customers’ time to market and we do that by digitizing the entire manufacturing process. From our front-end services to our proprietary processes on the manufacturing floor, you will find three consistent objectives: it’s fast, it’s easy, and it maintains the digital thread. The CyberGage360 comfortably fits all three of these needs. It is the synergistic solution we were seeking for our metrology lab and future metrology offerings.”

Back

Back

Back to News

Back to News