Benefit Summary

The SQ3000™ provides accurate, repeatable inspection data despite high height variation and increased shine in automotive parts.

Challenge

Our automotive customer had an existing 2D inspection solution for automotive parts with >10mm variation in height. The lack of 3D capability lead to a high escape rate and unreliable data. They were in the process of ramping up for mass production and needed to improve the line cycle-time without sacrificing performance. Catching defects earlier in the manufacturing process would help reduce operator costs and create efficiencies down the line.

This customer feared a 3D solution would be complicated to maintain and difficult to use, requiring an increase in operator costs. They were in search of an automated solution that could reduce costs overall to help them remain competitive, while producing a quality product for consumer use.

Solution

We worked with our customer to implement the SQ3000™ 3D Automated Optical Inspection (AOI) that integrates with their iTAC and MES systems. This versatile solution is easy to use and provides consistent, accurate results at high speeds. The sensor, software and system all work together to completely automate the full-line inspection process, with higher mean time between failures of the bonding inspected and a low-to-zero escape rate.

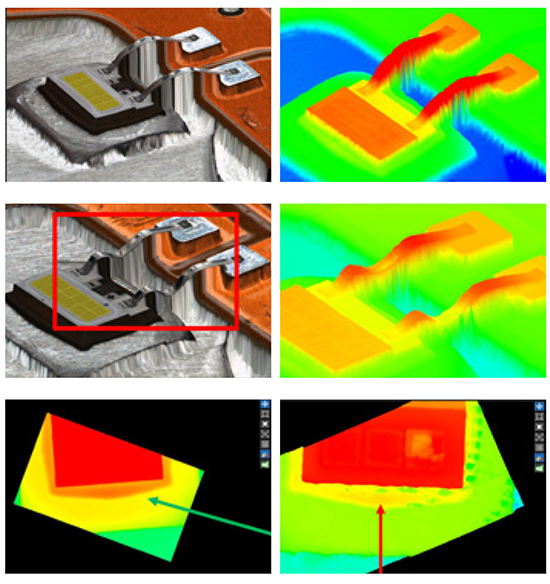

By implementing a full-line inspection process, our customer is able to identify and pinpoint defects sooner in the process for operator ease. The motion-scheduling algorithm is optimized to acquire high quality 3D data from the multi-height boards. In addition to general SMT inspection, our customer is able to quantify the die bonds and ribbon bonds accurately and repeatedly. This range of coverage provides reliable data for position, height, rotation, structure and more.

With the Multi-Reflection Suppression (MRS) technology, our customers are able to find defects sooner and mitigate any measurement inaccuracies due to shine or shadow, for high yield inspection at fast speeds.

This proprietary system is a best-in-class solution with a high-quality user interface that helps our customers build trust with their customers. It offers a remarkably low escape rate, reduces costs, improves yields and continues to create operational efficiencies.

Back

Back

Back to News

Back to News