Benefit Summary

From fast to faster, the SQ3000™ helps our customers with inspection in mass production environments at the highest speeds on the market, with unmatched accuracy and ease-of-use.

Challenge

Our customer had an existing 2D inspection solution with 3D capability, however it had a high escape rate. They were in the process of ramping up for mass production and needed to improve the cycle-time without sacrificing performance.

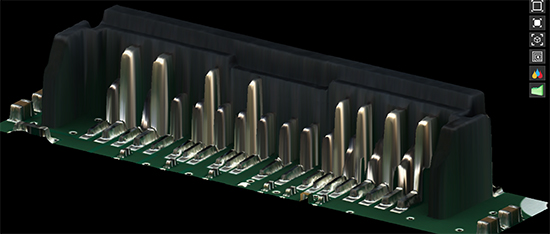

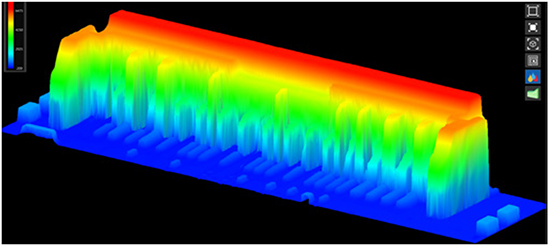

Their automotive entertainment systems contained tall connectors with multiple pins, and a 3D inspection with a robust motion-scheduling algorithm was required for accurate data at the solder joints. Catching defects earlier in the manufacturing process would help reduce operator costs and create efficiencies down the line.

The inspection speed this customer required exceeded the capability of the systems there were using.

Solution

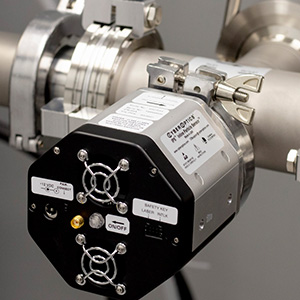

Our team met the speed requirements for inspection with the SQ3000™ to effectively meet their mass production needs. This versatile solution is easy to use and provides consistent, accurate results at the highest speeds on the market. The proprietary Multi-Reflection Suppression (MRS) sensor, software and system all work together to completely automate the full-line inspection process, with higher mean time between failures of the connectors inspected and a low-to-zero escape rate.

By implementing a full-line inspection process, our customer is able to identify and pinpoint defects sooner in the process with operator ease, reducing resources required for inspection. This process change allowed our customer to convert their offline defect review station to an X-Ray defect review station for increased accuracy. Our system also provides side camera inspection for defects not normally visible from a top view. And the sensor technology mitigates any measurement inaccuracies due to tall objects and component density.

This proprietary system was evaluated as a best-in-class solution with a high-quality user interface that helps our customers build trust with their customers given the highest commitment to quality. It offers a remarkably low escape rate, reduces costs, improves yields and continues to create operational efficiencies.

Back

Back

Back to News

Back to News