An Interview with RiteTrack, WaferSense Sweepstakes Prize Winner

Timothy McGovern, Engineering & Technical Support Manager for RiteTrack, recently won the WaferSense Sweepstakes prize and was asked why he chose the WaferSense ALS2200C leveling sensor.

Q: Why did you choose the WaferSense ALS2200C leveling sensor as your Sweepstakes prize over all other WaferSense wafer product offerings?

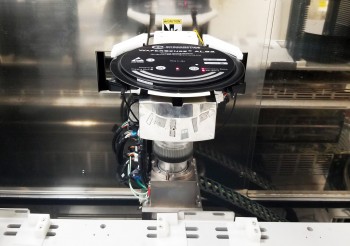

A: Being a company the specializes in the remanufacture of 200mm TEL, SVG and DNS track tools we have the greatest need for quick and accurate leveling of all wafer positions. Track tools have fast moving robots with dozens of chambers where proper leveling is absolutely critical to the smooth tool operation.

We have tried building home-grown devices and using traditional bubble-levels, but none really work nearly as fast and easy as the WaferSense ALS2 leveling wafer. Ultimately every other wafer leveling method except for ALS2 relies on “eye-balling” and ALS2 is the only way to get a tool leveled quickly and accurately. The LevelView software is easy to use and allows us the ability to keep permanent records and do 3D modeling of each chambers level status.

For example, if TEL Track wafer leveling is off then wafer breakage or pin breakage is at higher risk. ALS2 is particularly useful in leveling pins since unlevel pins can cause the wafer to “float” once it is placed on the chuck because on edge of the wafer is hitting before the other side and there really is no other practical method for such leveling tasks except for WaferSense ALS2.

RiteTrack is a remanufacturer of Semiconductor equipment specializing in TEL, SVG and DNS Track tools. As a leader in consolidated sales and support solutions for the semiconductor industry’s most popular mature production track equipment, they provide a bridge for fabs to continue capitalizing on their current equipment investments; offering extensive updates, equipment/parts sales, and technical services worldwide. www.ritetrack.com

Back

Back

Back to News

Back to News