Success Story – Packaging

Type of Customer

A leading international mass production packaging company.

Our Customer’s Requirements

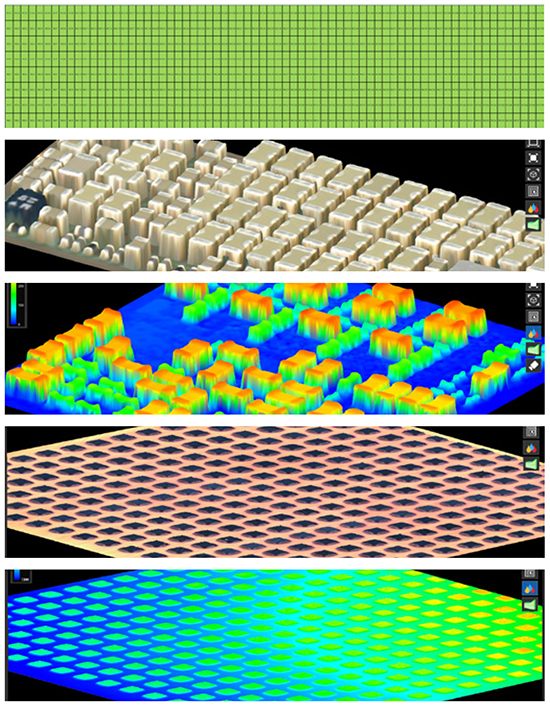

The company was in need of a high-speed, high-volume solution that effectively would increase inspection accuracy, improve traceability, and identify and categorize defects on boards and small components for mobile phone, tablet, and dense board applications. The ability to inspect 20k components – including very shiny ones – in 20 seconds was needed to ensure production requirements. Additionally, inspection sensitivity needed to be high enough to verify placement of 0201 metric components, which could not be done manually.

Our Solution – The CyberOptics SQ3000™ AOI System

By automating inspection, operator time and costs could be reduced, and production volumes could be increased with significantly fewer defective parts escaping detection. A 0201 inspection capability would deliver repeatability of 6 micrometer in 3 sigma, for X, Y and Z measurement. With comprehensive 2D and 3D inspection, text, rotation, position, cracked and damaged components, debris, gap measurement between components, and missing components would be detected, while 3D coplanarity inspection would ensure that all components were properly seated. Defects can be automatically categorized, enabling fast and accurate traceability. Our Multiple Reflection Suppression (MRS) technology effectively mitigates measurement inaccuracies.

The CyberOptics SQ3000 can be integrated as part of full line automation with existing Manufacturing execution systems (MES).

With minimal operator intervention, and a user-friendly interface, training time would be reduced, and operator time used more efficiently, providing a cost-effective competitive edge.

The stability of the SQ3000 means that there is higher mean time between failures of inspected components, often more than 35,000 hours.

Each of these factors contributes to reduced costs within the financial justification, while lower escape rates contribute to customer satisfaction, and a best in class solution.

The Result

Each of the customer’s objectives were met. On the production side, inspection was automated; the challenge of inspecting 20k components in 20 seconds was realized; production speeds were increased, and the number of escapes driven down. Defect categorization and accelerated traceability led to catching defects earlier in the process, thereby enabling them to be eliminated at their source, and more quickly than previously possible. With the cost, time and waste savings, all these improvements, made possible with the CyberOptics SQ3000, added value and enhanced customer relationships.

Back

Back

Back to News

Back to News