Success Story – Medical

Type of Customer

Our customers are major suppliers of medical equipment ranging from hearing aids to pacemakers.

Our Customer’s Requirements

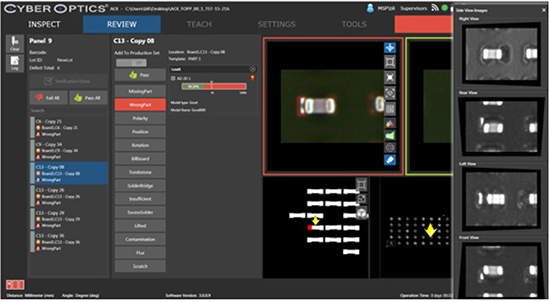

The level of dependence on technology in today’s healthcare is enormous, and optimal performance is essential. The size of boards and components, combined with a zeroescape, high defect detection rate, led these companies to seek an automated inspection solution with low operator intervention and maintenance times, tight process control, and a high level of traceability, including accurate barcode reading at the component level. A particularly challenging requirement was the need to read barcodes on the top of tall components to ensure part identity. Another factor driving the need for increased inspection accuracy was that the price of components in this industry is much higher than in others. Catching defects earlier in the manufacturing process can yield savings while at the same time improve product quality and reliability.

Our Solution – The CyberOptics SQ3000™ AOI System

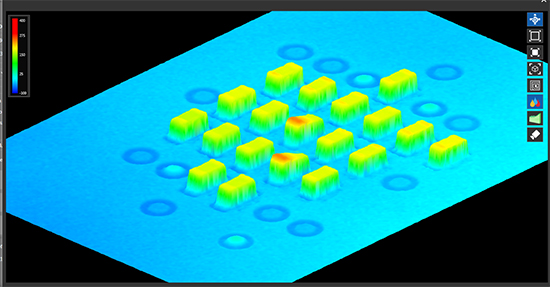

Automating the inspection process with the SQ3000 provides a solution that monitors and traces every component’s quality. It also inspects the fit of each component and ensures the integrity of every connection using 3D inspection. Inspecting components of different heights is not a problem, and text, numbers and barcodes can be read and automatically checked against specifications. The SQ3000’s robust technology delivers the lowest escape rates among automatic optical inspection (AOI) systems on the market, while its inspection and measurement algorithms achieves a high level of accuracy and repeatability. The system’s ultra-high-resolution and proprietary sensor is specifically designed for these applications. The SQ3000 also includes unique Multiple Reflection Suppression (MRS) technology that mitigates measurement inaccuracies arising from small and shiny surfaces found on very small dense boards. Each of these factors drives quality assurance up, and overall costs down.

The Result

All of the customers’ specifications were met. Operator costs were reduced; process control was tightened, and a high level of traceability achieved, thanks to componentlevel barcode verification. The SQ3000 made a major impact on customers’ existing overall quality control processes, which subsequently increased the satisfaction levels of their customers.

Back

Back

Back to News

Back to News