Success Story – Automotive Connectors

Type of Customer

Our customer is a leading manufacturer of automotive entertainment systems.

Our Customer’s Requirements

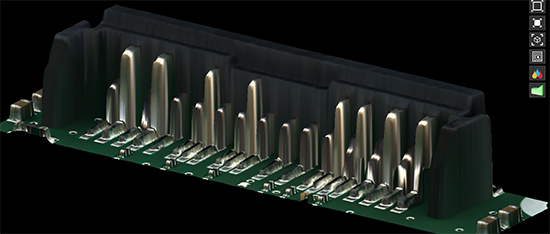

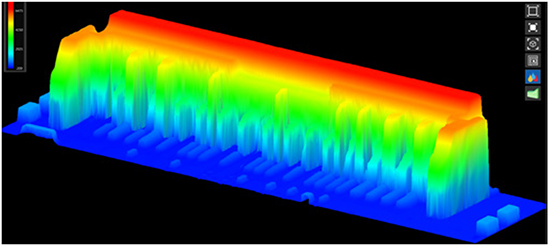

Our customer sought to increase the accuracy of tall connectors with multiple pins on SMT boards, and ensure the integrity and accuracy of connector solder joints. The company wanted to improve cycle times, while also lowering escape rates, and reducing costs. It had been using a 2D AOI system that that only been catching defects that were apparent from a single perspective.

Our Solution – The CyberOptics SQ3000™ 3D AOI System

Solution Overview – CyberOptics determined that 3D inspection with its SQ3000 solution could deliver the required speed, standard of defect detection, and overall cost reduction. We also determined that inspection earlier in the manufacturing process would make considerable savings. Automating the factory with manufacturing execution systems (MES) incorporated into the SQ3000 would further contribute to the desired result.

Speed – To help reduce cycle times, the field of view (FOV) of the cameras was increased. The precision of the SQ3000 system, optimized inspection algorithms with higher image acquisition speeds, and the fact that it was a 3D inspection, ensured that increase speeds did not compromise accuracy.

Cost Reduction – As part of the drive to accelerate production speeds, an SQ3000 was integrated into the company’s off-line X-Ray defect review station. In combination with inline inspections, traceability was also improved.

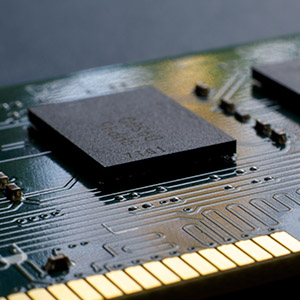

Inspection Coverage – Using the same proven approach for inspecting surface mount technology (SMT) boards for other industries, the SQ3000’s side cameras inspect all visible aspects, capturing the full range of defects, including those not visible in 2D inspection systems.

Sensor Technology – The SQ3000’s 3D Multi-Reflection Suppression (MRS) Sensor technology mitigates any measurement inaccuracies caused by tall objects, component density and shiny surfaces.

Ease of Use – Minimal operator intervention was needed, and programming times were reduced by a user-friendly, intuitive interface. Training time and maintenance times are also minimized. These characteristics result in reduced operational costs, and make the solution ideal for global implementation.

Reliability – This customer has experienced significantly higher mean times between failures of the connectors inspected.

Reduced Costs – Overall inspection costs have been reduced with the SQ3000 systems and increased factory automation, delivering a cost profile within the company’s financial justification.

The Result

All the company’s objectives were met: production speeds have increased; costs reduced; and the number of escapes cut. The powerful combination of automation, inspection earlier in the process, and the CyberOptics SQ3000 has delivered all that this customer required, with consequential improvements in satisfaction down the supply chain.

Back

Back

Back to News

Back to News