Improving Yields with the Best Known Method (BKM) for Fast and Highly Accurate Airborne Particle Sensing

Join the team at Semicon Japan, Tokyo Big Sight, December 13-15th at Booth #5402.

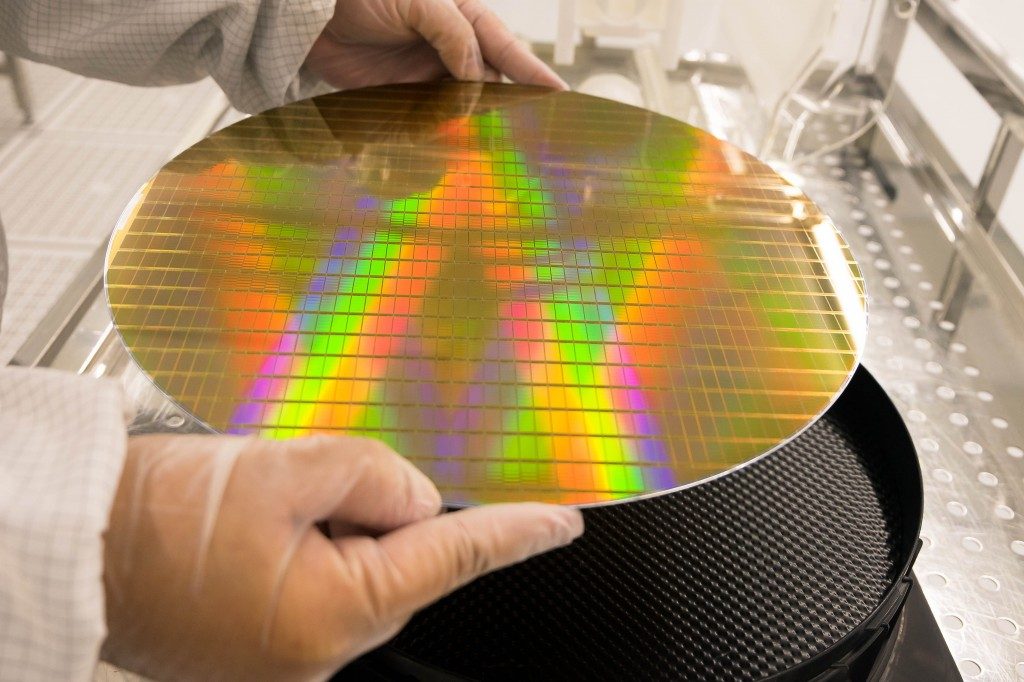

WaferSense® and ReticleSense® measurement devices deliver 3 compelling bottom lines.

Save Time ~ 88% reduction, half the manpower

Save Expense ~95% reduction

Increase Throughput ~20X

What can the WaferSense and Reticle Sense Airborne Particle Sensors do for your fab?

Improve equipment set-up and long-term yields by wirelessly monitoring airborne particles in real-time.

Speed equipment qualification with wireless measurements.

Collect and display particle data wirelessly using the Airborne Particle Sensors and software for real-time equipment diagnostics.

Compare past and present as well as one tool to another.

Save time by swiftly locating contamination sources and see the effect of cleanings, adjustments and repairs in real-time.

Shorten equipment maintenance cycles.

Detect particles in real-time without opening the tool, so you don’t need to expose process areas to the environment.

Easily find the place where particles contaminate wafers with the thin and light Airborne Particle Sensors.

Selectively clean tools once the particle location is identified.

Lower equipment expenses with objective and reproducible data.

Raise your first-pass monitor wafer success, reduce your qualification expense and increase availability.

Receive early warnings for impending equipment failures and optimize your preventative maintenance plans.

Establish a baseline from a known clean tool, then cycle the Airborne Particle Sensor through a candidate tool before committing monitor wafers.

Back

Back

Back to News

Back to News