Benefit Summary

Our Ultra High-Resolution Multi-Reflection Suppression (MRS) sensor accurately and repeatedly provides quality inspection data of critical components to detect defects and lower the escape rate for medical applications.

Challenge

Our medical customers have rigorous inspection processes for hearing aid and pacemaker components. These critical components have higher price points and impact people’s quality of life, so the quality of inspection is of the utmost importance. These customers would benefit greatly from the ability to catch defects sooner in the process to help manage costs throughout the inspection cycle.

For this particular application, our customers need an automated inspection system

that can gather reliable data from various heights on a dense board, including hard-toread

barcodes. A robust and flexible inspection and measurement algorithm solution is

required to achieve accurate, repeatable results.

Solution

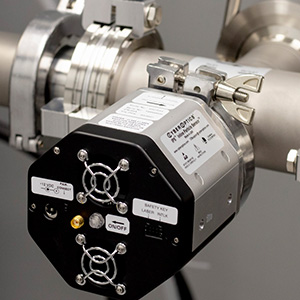

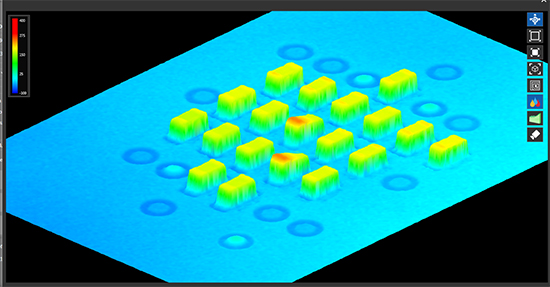

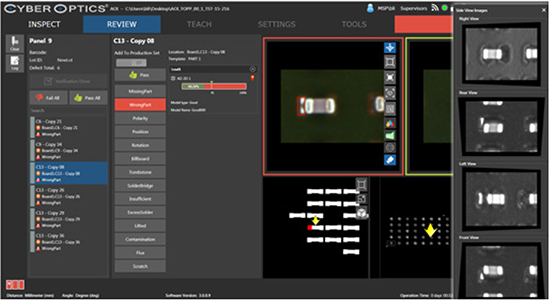

To ensure a high degree of accuracy, we worked with our customers to integrate the SQ3000™ 3D Automated Optical Inspection (AOI) system into their manufacturing process. The sensor, software and system all work together to completely automate the full-line inspection process, offering the lowest escape rate among AOI solutions available in the market. With the multi-view side cameras in the Ultra High-Resolution MRS sensor and sophisticated measurement algorithms, this solution offers a low-to-zero escape rate.

By implementing a full-line inspection process with MRS technology, our customers are able to find defects sooner and mitigate any measurement inaccuracies due to height variations, shine or shadow, reducing costs and operator time. This versatile solution is easy to use, reduces training time and provides consistent, accurate results.

The SQ3000™ with a high-quality user interface helps our customers build trust with their customers based on the best-in-class evaluation and commitment to the highest quality. The systems continue to improve yields and operational efficiencies.

Back

Back

Back to News

Back to News