Advanced MRS Sensors for Semiconductor Applications at SEMICON China

CyberOptics Showcases Advanced MRS Sensors for Semiconductor Applications at SEMICON China

CyberOptics® will demonstrate the proprietary 3D Ultra High-Resolution Multi-Reflection Suppression (MRS) Sensor technology and the next-generation WaferSense® Airborne Particle Sensor (APS3) in Booths # 5676 and 1145 at SEMICON CHINA, March 20 – 22 at the Shanghai New International Expo Centre.

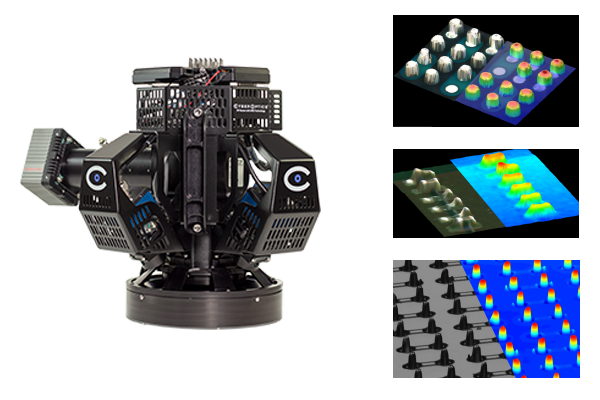

MRS Sensor technology meticulously identifies and rejects reflections caused by shiny components and surfaces. Effective suppression of multiple reflections is critical for highly accurate measurements. Offering an unmatched combination of accuracy and speed, MRS sensors are widely used for inspection and measurement in the SMT, metrology and semiconductor markets. This best in class, ultra high-resolution technology incorporated into KLA®’s back-end inspection systems, is ideally suited for IC package, wafer bump inspection and mid-end semiconductor applications where the highest degree of precision is required.

CyberOptics will also demonstrate its next-generation WaferSense® Airborne Particle Sensor™ (APS3) 300mm with new ParticleSpectrum™ software that quickly monitors, identifies and enables troubleshooting of airborne particles in real time within semiconductor process equipment and automated material handling systems. The wireless device speeds equipment qualification, shortens equipment maintenance schedules and lowers equipment expenses. Now in a thinner and lighter form factor to travel through semiconductor tools with ease, the APS3 offers leading accuracy and sensitivity.

The APS3 solution includes ParticleSpectrum software – a touch-enabled interface with user-friendly functionality, making it simple to read, record and review small to large airborne particle data from multiple devices. Engineers can easily identify when and where the particles originate and see the effects of cleanings, adjustments and repairs in real-time.

Back

Back

Back to News

Back to News