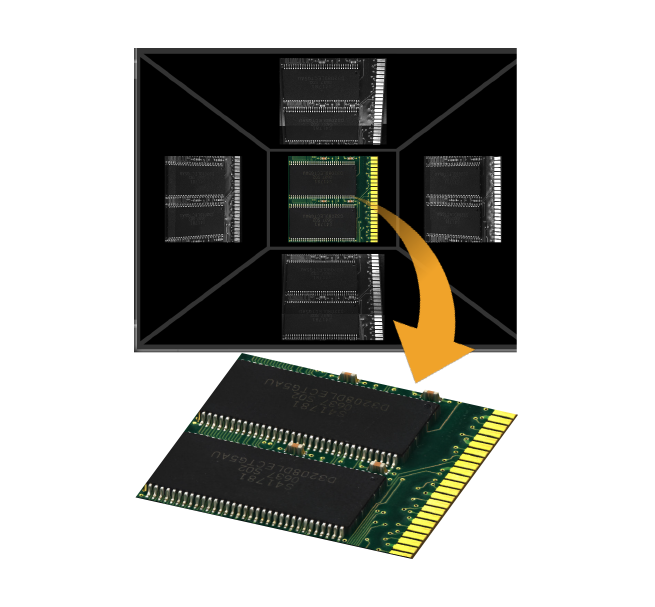

The MX3000™ is powered by CyberOptics’ breakthrough 3D sensing technology comprising of two MRS® Sensors delivering simultaneous dual-sided automated final vision inspection for singulated memory modules – for metrology grade accuracy at production speed.

The system provides in-line defect review stations and auto sorts false calls into good trays after review, is fully automation-ready, SECS/GEM and S2/S8 compliant.

Multi-Reflection Suppression® (MRS®) Technology

Flexibility At Its Best

Faster, Smarter Programming

MRS technology suppresses any reflections that can distort the data, especially on shiny components, enabling precise 3D representation while the architecturally superior sensor design captures and transmits data simultaneously and in parallel. The result is unmatched speed and accuracy.

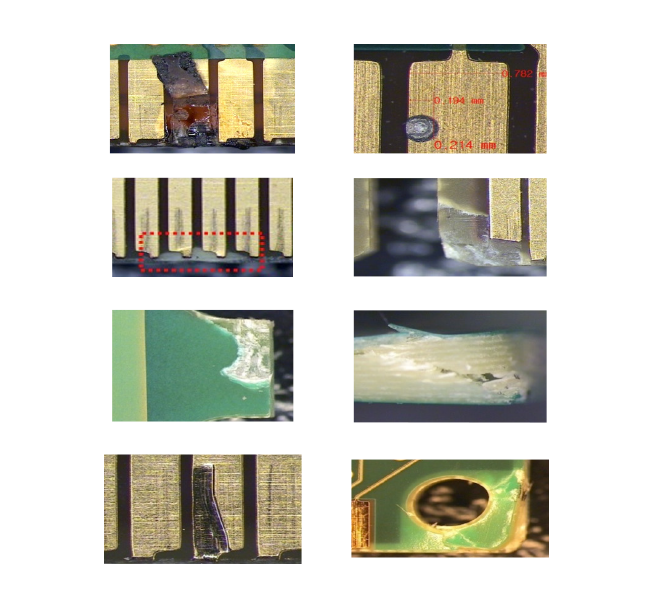

Post-test defect types and pre-shipping inspection capabilities

include: Components Edge,

Damaged PCB Corner, Goldfinger Discolored / Burnt / Badly Scratched, Gold Tab Inspection – Lifted Tie Bar, Burnt, Contamination,

Physically Damaged Components

Inspection Speed

50 cm2/sec (2D+3D)

Resolution

Sub 10 μm

Board Length

Board Width

Min. 25 mm / Max. 140 mm

Min. 17 mm / Max. 35 mm

Component Height Clearance (max)

35mm

Component Types Inspected

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

pins, and more

Solder Joint Defects Categories

Solder bridge, opens, lifted leads, wettability, excess and insufficient solder, debris, and more

3D Measurement inspection

Lifted lead, package coplanarity, polarity dimple and chamfer identification

Other Items Detected

Gold-finger contamination, pin-in-hole, bent pins, debris, OCR/OCV and many others