Success Story – Through Hole Technology

Type of Customer

Our customer is a leading manufacturer of high-power water pumps.

Our Customer’s Requirements

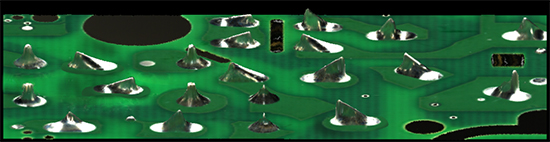

Our customer wanted a new solution for inspecting through-hole (tht) technology, printed circuit boards (PCB). Its existing solution was a 2D automatic inspection system (AOI), which was signaling many false calls that were costing time and money. Throughthe- hole technology has many variations in shape and color, making accurate inspection difficult, especially at speed.

The objectives for any new system were higher production speeds and volumes, and lower operator costs. Elimination of false calls and associated errors in inspection were also a priority.

Our Solution – The CyberOptics SQ3000™ 3D AOI System

The company needed to automate production with a robust and flexible sensor solution that could accurately inspect tht and accommodate the variations caused by different soldering machines that had been problematic. The new system also needed to accurately inspect shiny components that had also been a cause of inaccurate data.

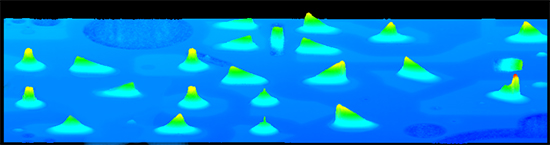

CyberOptics installed multiple SQ3000 systems to reduce cycle times and ensure product integrity. The SQ3000 was integrated into the factory’s automated production line and inspections delivered a first-pass yield (FPY) of more than 98 percent, a huge improvement of the previous 80 percent. Moreover, volume, height and area variations

were accurately inspected using 3D imaging technology. CyberOptics’ proprietary Multiple Reflection Suppression (MRS) technology mitigates any measurement inaccuracies due to shiny components. Ease of use and higher mean times between failures of the products they produce, reduced operator interventions and training times, driving down costs.

The Result

After extensive evaluation and subsequent installation, all objectives were met. Automation accelerated production, while the SQ3000’s 3D inspection, with accurate readings down to 0201 metric, cut false calls and escapes, and reduced operator costs. Problems with variations in tht boards and shiny components were virtually eliminated. Defects can now be easily qualified, and fast, accurate traceability is further reducing costs, while improving quality control.

The CyberOptics systems have achieved the company’s goals in its financial justification, and further improved its reputation for quality control among its customers.

Back

Back

Back to News

Back to News