Success Story – Solder Paste Inspection

Type of Customers

Our customers for SPI are international providers of specialist technologies for a full range of vertical markets.

Our Customers’ Requirements

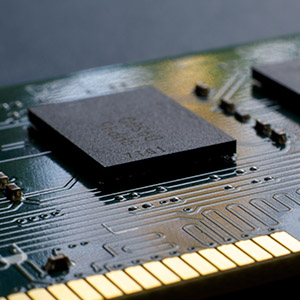

Our customers needed a robust and flexible sensor solution to obtain reliable data from solder paste inspection (SPI) and automated optical inspection (AOI) products. SPI systems need to measure very small, short objects (~50 μm), while AOI was needed to measure objects up to 25 mm tall.

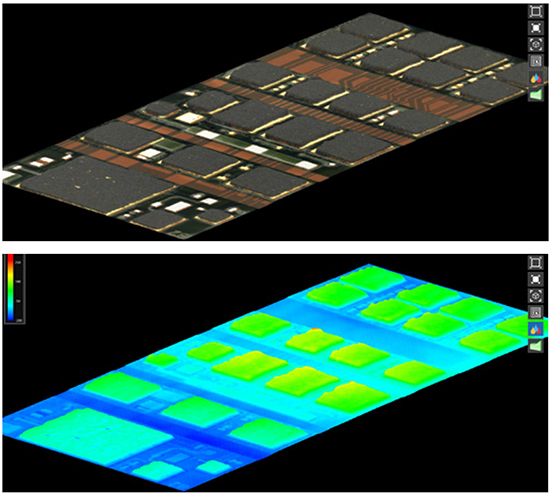

Our Solution – The CyberOptics SQ3000™ AOI System

Inspection performance – The SQ3000would provide reliable, repeatable inspection of 6 micrometers in 3 sigma for X, Y, Z measurement.

Inspection coverage – The SPI and AOI combination would provide detailed inspection data of objects of any height.

Sensor technology – The SQ3000 is capable of acquiring reliable data for the wide height range of SPI and AOI applications.

Ease of Use – The SQ3000 provides both types of inspection (SPI and AOI) in one software package. The same operator can oversee both functions after a single training course.

Reduced risk – With the flexibility of the SQ3000 there is reduced rink in changing production layouts in the future.

Best-in-class solution – The high-quality sensor, system and software provide a good impression to our customers’ customer quality management teams.

The Result

The CyberOptics SQ3000 is a flexible multiple application solution delivering both SPI and AOI data with the same reliability. Using single machine for both types of inspection minimizes the foot print, and saves investment costs. Only one set of spare parts is needed for both applications, and since only one skill set is needed to run both applications, operators can be training in a single course.

The SQ3000 can be used in environments where there are changes in progress, and with pilot line designs.

All customer objectives were met for both SPI and AOI functionality.

Back

Back

Back to News

Back to News