Success Story – Semiconductor

Type of Customer

Our customer is a major international semiconductor manufacturer.

Our Customer’s Requirements

Our customer wanted an inspection system for DRAM, SDRAM, and SSD memory cards. These products included small 0201 metric components that could not be manually inspected.

As the company intended to achieve mass production volumes, speed with quality assurance was vital. It was also important to reduce operator costs to ensure competitiveness.

Our Solution – The CyberOptics SQ3000™ AOI System

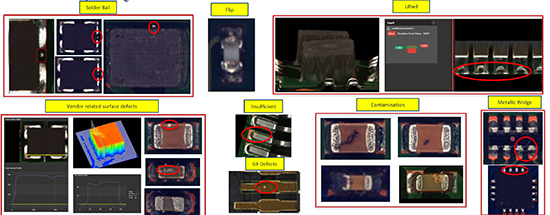

Our customer needed a 3D automated solution that would capture defects earlier in the manufacturing process. Factory automation combined with a robust and reliable sensor solution would ensure fast inspection while providing accurate data. It would also need to accommodate variation in the evolution of the product, and inspect gold fingers, and detect non wet flux, missing parts, and correct component alignment.

The SQ3000 has the lowest escape rate on the market. By optimizing inspection algorithms, line cycle times could be accelerated. Increased efficiency and automation would reduce the need for operator intervention, while the easy user interface would reduce programming and training times, further reducing times.

The SQ3000’s Multiple Reflection Suppression (MRS) sensor technology would mitigate reflections that can lead to measurement inaccuracies and false reading caused by small and shiny components. The system would be reliable, stable, and have higher mean time between failures of the components inspected.

The Result

All customer objectives were met. Escape rates were lowered, operator costs reduced, and quality assurance levels increased. Defects were qualified, and traceability facilitated. The company’s customer valued the overall commitment to the highest quality standards.

Back

Back

Back to News

Back to News