Success Story – Mobile Phone Camera Module

Type of Customer

Our customer is a leading global electro-mechanics manufacturer.

Our Customer’s Requirements

In a fast-paced and highly complex mobile phone camera module production environment, operators involved in a manual inspection process can easily miss component defects. Whether the issue arises from fatigue or simply an unexpected fault that gets overlooked, the scope for error can be high.

Our customer was experiencing this problem and needed a solution that not only overcame this issue, but also provided a high-speed, reliable and accurate inspection sensor for shiny solder joints. In addition, the sensor needed to be flexible as the camera modules produced by this company are continually upgraded (at least once every 6 months) and therefore the inspection requirements would often change.

Our Solution – The CyberOptics SQ3000™ 3D AOI System

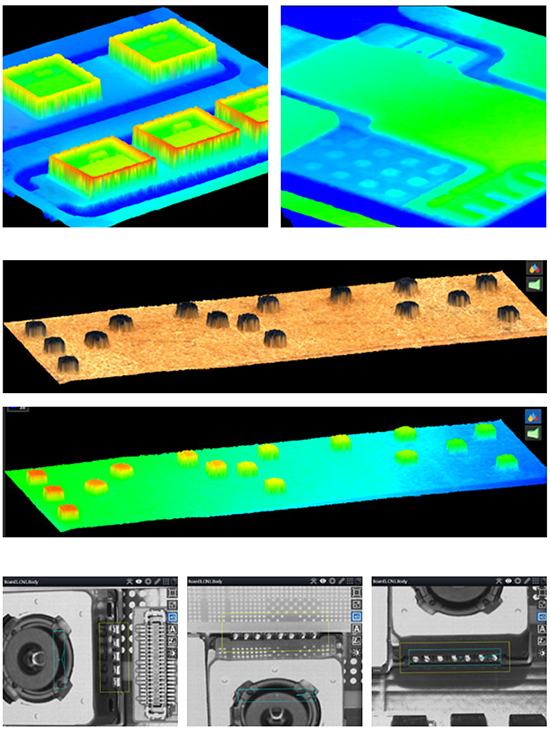

In-Line and Automated – The SQ3000 integrates seamlessly into existing production lines. This company integrated its system to the existing stocker and flipper and, with a now fully automated inspection process, was able to reduce the high cost and inaccuracy associated with manual inspection.

High Speed – Faster than traditional CMM systems, the SQ3000 enabled this company to achieve the speed required for mass production within the line cycle time, requiring just one SQ3000 to achieve the same speed as six soldering machines.

Inspection Performance – To deliver the flexibility this customer required, the SQ3000 featured AI2 capability and a unique inspection algorithm to obtain reliable data every time the camera module was upgraded or modified.

Comprehensive and Accurate Inspection – With CyberOptics’ market-leading, high-resolution Multiple Reflection Suppression (MRS) technology, the SQ3000 was able to achieve a significantly lower escape rate and mitigate any measurement inaccuracies due to shiny solder joints. The proprietary, high-resolution sensor also provides

extensive inspection coverage, which included open/short circuit, excessive solder, cold joint and burn mark.

Reliable and Easy to Use – Since installing the SQ3000, this company has reported a higher mean time between failures of the products they produce. With minimal training required to operate the system and less intervention required to maintain it, cost-efficiencies have been made and programming and set-up time has been reduced. This company predicts that it will see a full return on investment in less than 4 years.

The Result

Installing the SQ3000 has met and exceeded this company’s expectations. With a fully automated, high-speed, reliable and flexible solution, the system has enabled the company to overcome its unique challenges, as well as improve production speed and lower escape rates.

Back

Back

Back to News

Back to News