Resolving Particle Issues In Photolithographic Scanners

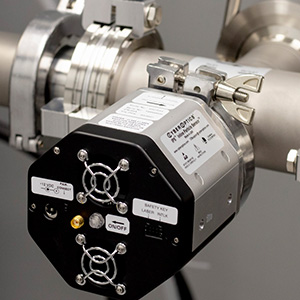

CyberOptics’ ReticleSense® Airborne Particle Sensor™ (APSRQ) improves longterm

yields and equipment setup by wirelessly monitoring airborne particles in real time. This innovative device can be loaded directly into a photolithographic scanner, quickly identifying source of contamination.

The ReticleSense Airborne Particle Sensor checks the entire reticle path inside the tool, not just the reticle surface. This tool detects precisely when and where particles are occurring in scanners, allowing individual components to be replaced rather than entire kits.

Challenges With Particle Detection

It’s essential to quickly identify the source of airborne particles in photolithographic scanners—both to coordinate and confirm the effects of cleanings and repairs. Regrettably, most traditional methods for detecting particles have trouble addressing particle issues proactively.

Consider in-situ methods as an example. Conventional in-situ scanners do not provide access to real-time feedback, allowing particle sources to go undetected for significant amounts of time. These limitations make these legacy methods impractical for particle identification and management.

CyberOptics has tested in-situ scanners across a variety of photolithography tools with excess particles to measure their efficacy. Across these tests, the in-situ particle scanners would scan monitor reticles going in clean—but intermittently exit with significant amounts of particles of unknown origin.

Particle contamination was a constant source of frustration, namely because traditional methods of detection (such as built-in, monitor reticles, and bench-top particle counters) were unsuccessful in identifying the particle source.

ReticleSense Airborne Particle Sensor (APSRQ)

The APSRQ ReticleSense Particle Sensor brings a number of advantages when used in photolithographic scanners for quick particle qualification. APSRQ provides all the necessary alignment and fiducial marks, loading directly into a scanner to travel the entire reticle path. Through this process, the sensor detects exactly when and where particles are occurring in scanners in real time.

APSRQ technology streamlines the time-consuming task of partitioning with multiple surface scan reticles, which require the high-value scanner to be brought offline for lengthy troubleshooting. As a result, APSRQ requires significantly less manpower and downtime compared to conventional detection tools.

Using the APSRQ

Step 1: APSRQ is loaded into the tool. Most sections are found clean (zero particles).

Step 2: A particle spike occurs and is identified by the built-in particle scanner.

Step 3: Once the particle source is found, corrective action is taken for all associated moving parts.

APSRQ Particle Sensor Results

Back

Back

Back to News

Back to News