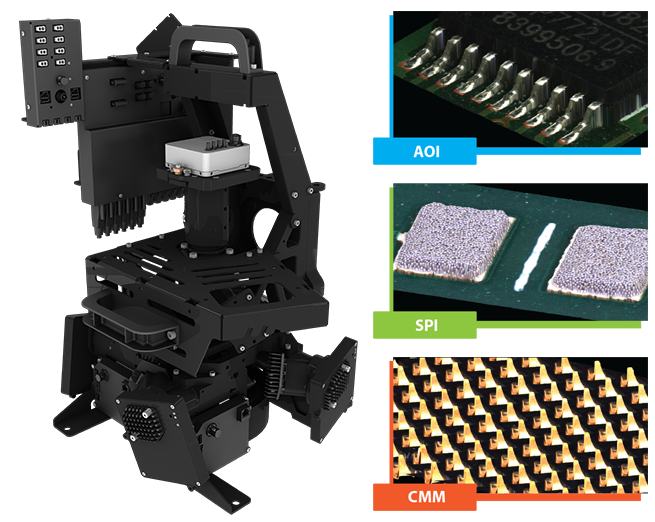

SQ3000+ Multi-Function System with Multi-Reflection Suppression® (MRS®) sensor technology provides the ultimate combination of high resolution, high accuracy and high speed for inspection and metrology. It remains the only system on the market capable of performing AOI, SPI and CMM in-line.

Ultra-High Resolution, 5 Micron - Multi-Reflection Suppression (MRS) Technology

Inspection and Metrology Solution for Assembly and Process Improvement for Advanced Applications

Intuitive, Easy-to-Use Software - Enable Smarter, Faster Inspection

Faster, Highly Accurate Coordinate Measurement (CMM) Suite

The new, ultra-high resolution 5 micron MRS sensor incorporated into the SQ3000+ is specifically designed for advanced applications with the most demanding requirements.

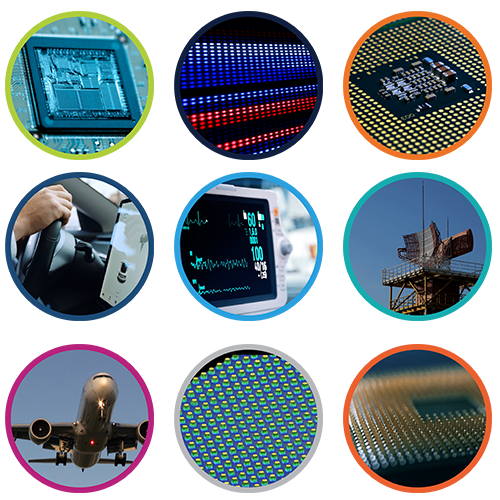

The SQ3000+ with MRS technology is ideal for high-end applications including advanced packaging, mini/micro LED, advanced SMT applications for automotive, medical, military, aerospace and advanced electronics, 008004/0201 solder paste inspection (SPI), socket metrology and other high-end coordinate measurement (CMM) applications where quality and reliability are critical.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

16 cm²/sec (2D+3D)

Minimum Component Size

0201 mm (008004 in.)

PCB Size

Minimum: 50 x 50 mm (2 x 2 in.);

Maximum: 420 x 320 mm (16.5 x 12.5 in.)

Component Height Clearance

Top: 20 mm ; Bottom: 50 mm

Resolution XY / Z

5 µm / 0.1 µm

Field of View (FOV)

25 x 25 mm

Maximum Weight (PCB or Sample)

10 kg

Min./ Max. Feature Height:

Min. 10 µm ; Max. 400 µm at spec, 2.4 mm capability

Component Types Inspected

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

pins, and more

Component Defects

Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more

Solder Joint and Other Defects

Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins

Coordinate Measurement

Capability

Line / Distance / X,Y / Mid Line, Inter Point / Regression Shifted, Datum X,Y / LSF X,Y Offset,

X,Y Offset / Value / Location / List of X,Y Values, Height / Local Height / Regression / Radius, Coplanarity/ Distance to plane / 2nd Order fitting, Difference / Absolute / 2sqrt / VC, Max / Min / Ave / Sigma / Plus / Minus / Multiple

See brochure for additional information.