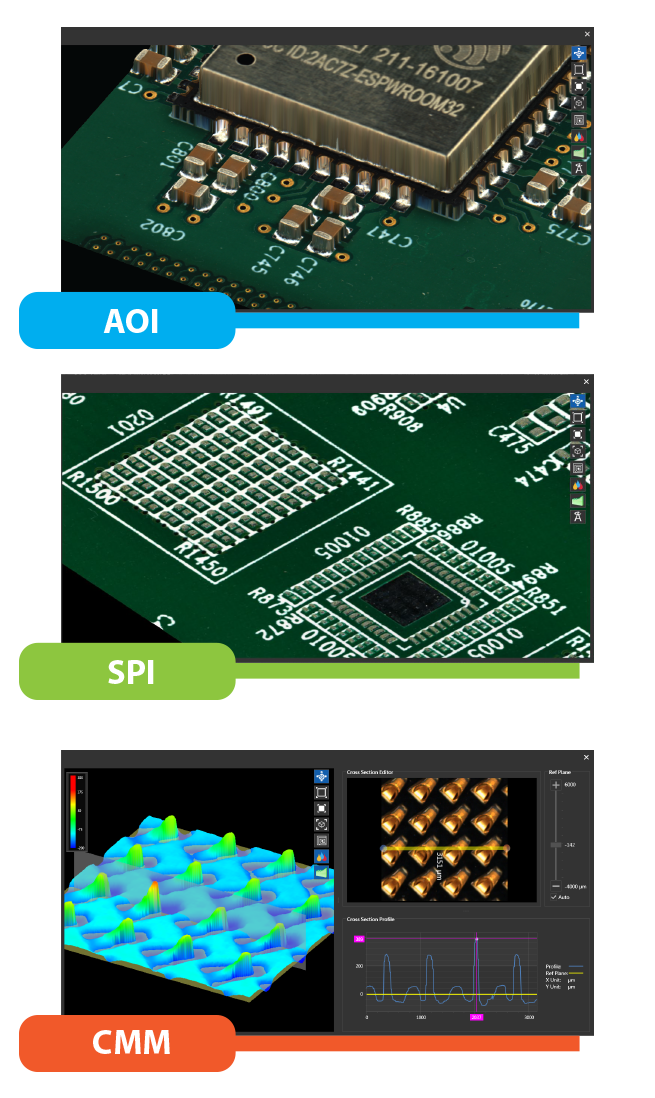

The SQ3000 is an all-in-one solution that’s loaded with powerful tools that cover inspection and measurement for Automated Optical Inspection (AOI), Solder Paste Inspection (SPI) and coordinate measurement (CMM) applications.

Metrology-Grade Accuracy

High Speed Inspection

Fast, Smart, Easy-to-use software

The SQ3000 offers unmatched accuracy with the revolutionary Multi-Reflection Suppression (MRS) technology by meticulously identifying and rejecting reflections caused by shiny components. Effective suppression of multiple reflections is critical for accurate measurement, making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

Standard MRS Sensor: 40 cm²/sec (2D+3D)

High-Speed MRS Sensor: 50 cm²/sec (2D+3D)

High-Resolution MRS Sensor: 20 cm²/sec (2D+3D)

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D)

Field of View (FOV)

Standard MRS Sensor: 36 x 30 mm

High-Speed MRS Sensor: 36 x 36 mm

High-Resolution MRS Sensor: 26 x 26 mm

Ultra-High Resolution MRS Sensor: 21 x 21 mm

X Y Resolution

Standard MRS Sensor and High-Speed MRS Sensor: 10µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 7µm

Z Resolution

0.5µm

Component Types Inspected

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

pins, and more

Component Defects

Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more

Solder Joint and Other Defects

Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins

Coordinate Measurement

Capability

Line / Distance / X,Y / Mid Line, Inter Point / Regression Shifted, Datum X,Y / LSF X,Y Offset,

X,Y Offset / Value / Location / List of X,Y Values, Height / Local Height / Regression / Radius, Coplanarity/ Distance to plane / 2nd Order fitting, Difference / Absolute / 2sqrt / VC, Max / Min / Ave / Sigma / Plus / Minus / Multiple