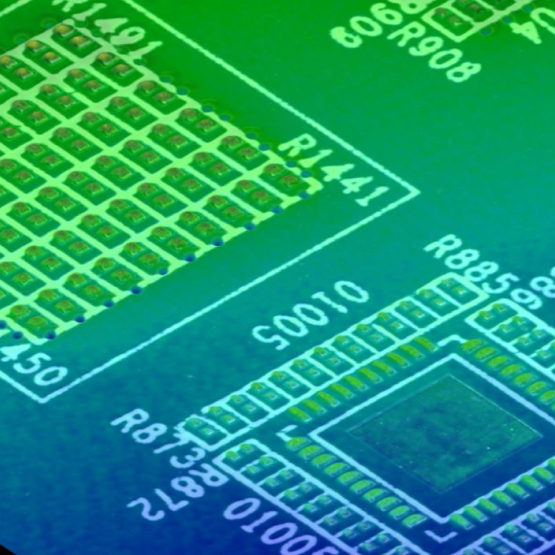

SQ3000

SQ3000™ for SPI

Ultimate in Speed and Accuracy

Metrology-Grade Accuracy

High Speed Inspection

Fast, Smart, Easy-to-use software

CyberOptics’ unique sensor architecture with 4 multi-view 3D sensors and a parallel projector, simultaneously captures and transmits multiple images in parallel while proprietary 3D fusing algorithms merge the images together, delivering metrology grade accuracy at production speed.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

Standard MRS Sensor: 40 cm²/sec (2D+3D)

High-Speed MRS Sensor: 50 cm²/sec (2D+3D)

High-Resolution MRS Sensor: 20 cm²/sec (2D+3D)

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D)

Minimum Component Size

Standard MRS Sensor and High-Speed MRS Sensor

0402 mm (01005 in.)

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor

0201 mm (008004 in.)

Board Size

SQ3000: Min. 50 x 50 mm, Max. 510 x 510 mm

SQ3000-X: Min. 50 x 120 mm, Max. 710 x 610 mm

Resolution

Standard MRS Sensor and High-Speed MRS Sensor: Sub 10µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 7µm

Component Height Clearance

Top: 50 mm ; Bottom: 30mm

Component Types Inspected

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header

pins, and more

Component Defects

Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more

Solder Joint and Other Defects

Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins

3D Measurement Inspection

Lifted Lead, package coplanarity, polarity dimple and chamfer identification

Solder Paste Inspection

Height, area, volume, registration and bridge detection