Powered by MRS Technology

SQ3000™ CMM

Fast and highly accurate with repeatable and reproducible measurements for metrology applications in the manufacturing of a wide variety of products such as PCBs, semiconductors and consumer electronics.

Fast and highly accurate with repeatable and reproducible measurements for metrology applications in the manufacturing of a wide variety of products such as PCBs, semiconductors and consumer electronics.

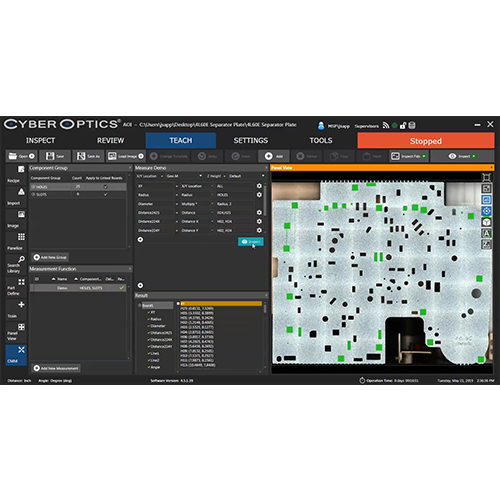

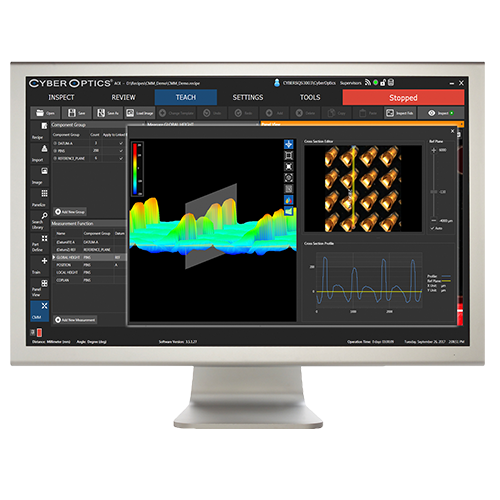

SQ3000 CMM utilizes CyberCMM™, a comprehensive software suite of coordinate measurement tools that provides highly accurate, 100% metrology-grade measurement on all critical points much faster than a traditional CMM, including coplanarity, distance, height and datum X, Y to name a few. A fast and easy set-up can be performed in less than an hour for programming complex applications as compared to slow, engineering resource-intensive set-up that typically requires multiple adjustments with traditional coordinate measurement machines (CMM).

Fastest – Seconds, not Hours

Easy-to-use Interface

Metrology-grade Accuracy

SQ3000 3D CMM offers unmatched accuracy with the advanced MRS technology by meticulously identifying and rejecting reflections caused by shiny components making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

The Ultra High-Resolution MRS sensor enhances the SQ3000 CMM platform, delivering superior performance ideally suited for Socket Metrology and micro-electronics applications where an even greater degree of accuracy and inspection reliability is critical.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

Standard MRS Sensor: 40 cm²/sec (2D+3D)

High-Speed MRS Sensor: 50 cm²/sec (2D+3D)

High-Resolution MRS Sensor: 20 cm²/sec (2D+3D)

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D)

Field of View (FOV)

Standard MRS Sensor: 36 x 30 mm

High-Speed MRS Sensor: 36 x 36 mm

High-Resolution MRS Sensor: 26 x 26 mm

Ultra-High Resolution MRS Sensor: 21 x 21 mm

Coordinate Measurement

Capability

Line / Distance / X,Y / Mid Line, Inter Point / Regression Shifted, Datum X,Y / LSF X,Y Offset,

X,Y Offset / Value / Location / List of X,Y Values, Height / Local Height / Regression

Radius, Coplanarity/ Distance to plane / 2nd Order fitting, Difference / Absolute / 2sqrt / VC, Max / Min / Ave / Sigma / Plus / Minus / Multiple

X Y Resolution

Standard MRS Sensor and High-Speed MRS Sensor: 10µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 7µm

Z Resolution

0.5µm

Accuracy XY

Standard MRS Sensor and High-Speed MRS Sensor: 6µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 5µm

Accuracy Z

2 μm

Minimum Feature Size

Standard MRS Sensor and High-Speed MRS Sensor: 100µm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 70µm

Maximum Feature Size

SQ3000: 510 x 510 mm (20 x 20 in.)

SQ3000-X: 710 x 610 mm (27.9 x 24 in.)

Minimum Feature Height

50 μm

Maximum Feature Height

Standard MRS Sensor and High-Speed MRS Sensor: 24mm

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 8mm