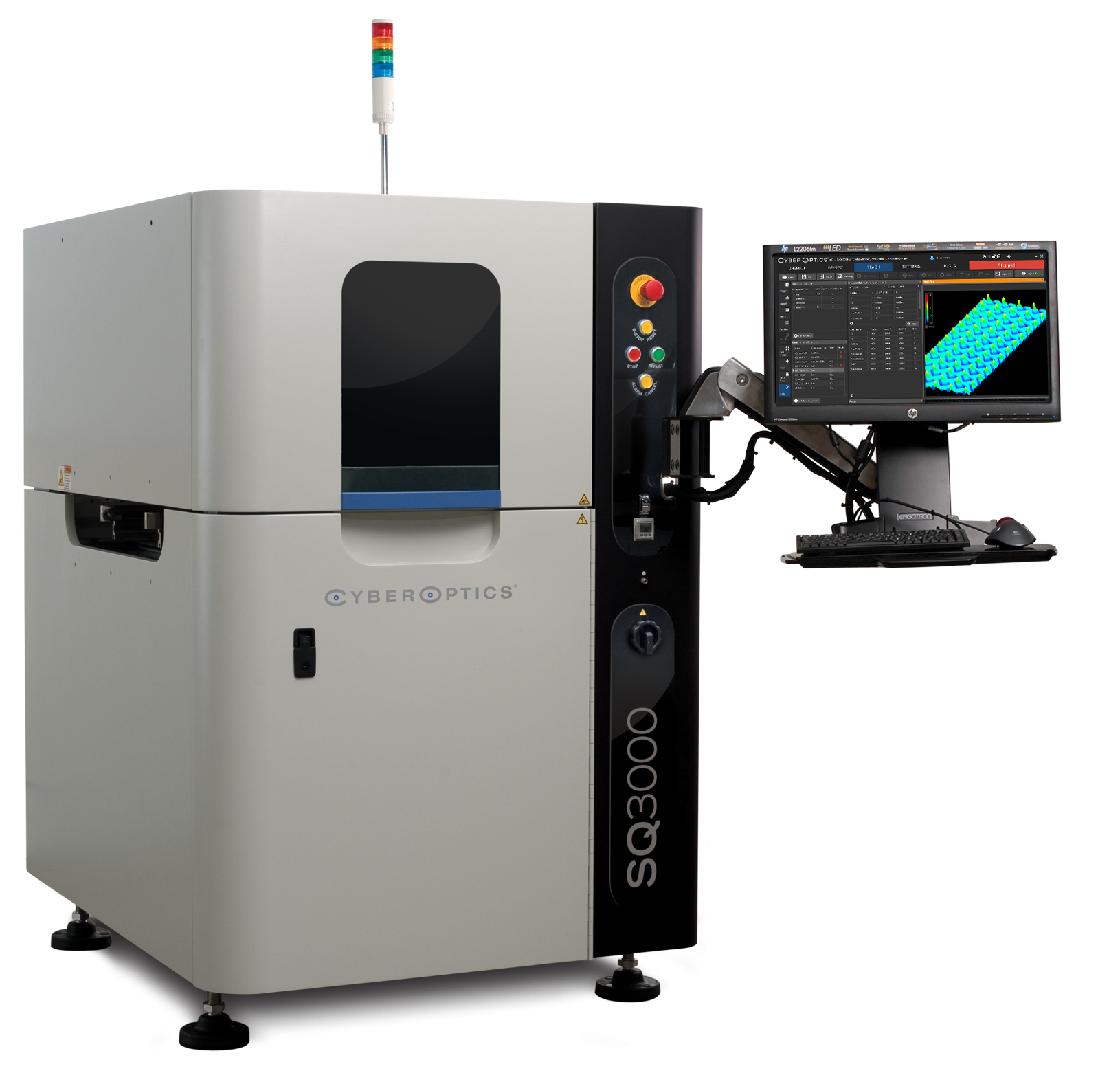

SQ3000™ CMM utilizes CyberCMM™, a comprehensive software suite of coordinate measurement tools that provides highly accurate, 100% metrology-grade measurement on all critical points much faster than a traditional CMM, including coplanarity, distance, height and datum X, Y to name a few. A fast and easy set-up can be performed in less than an hour for programming complex applications as compared to slow, engineering resource-intensive set-up that typically requires multiple adjustments with traditional coordinate measurement machines (CMM).

Fastest – Seconds, not Hours

Significantly speeds attaining coordinate measurements vs. traditional CMMs. Reduces engineering resource time.

Easy-to-use Interface

Simplifies process with award-winning, intuitive, touch screen experience. Quick programming for complex applications. Multi-process capable – AOI, SPI, AOM, CMM

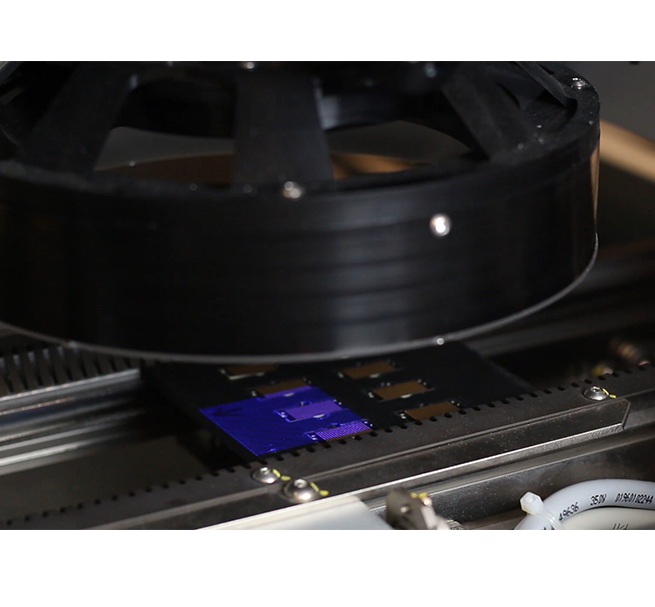

Metrology-grade Accuracy

Achieve metrology-grade accuracy with MRS®-enabled technology. Repeatable and reproducible measurements for metrology, semiconductor, microelectronics and SMT applications.

Back

Back