A LEAP FORWARD IN SOLDER PASTE INSPECTION

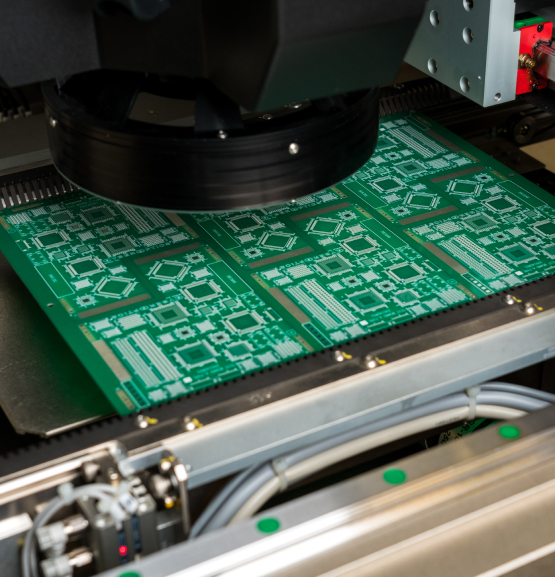

SE3000™/ SE3000-X™ 3D SPI

Maximize yields with the World’s First SPI system incorporating the MRS® Sensor technology. When only the very best will do.

Maximize yields with the World’s First SPI system incorporating the MRS® Sensor technology. When only the very best will do.

Metrology Grade Accuracy

High Speed Inspection + High Resolution Inspection

Fast, Smart, Easy-to-use software

The SE3000 SPI System brings the revolutionary MRS® technology to solder paste inspection delivering higher performance in accuracy and precision. Effective suppression of multiple reflections is critical, making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

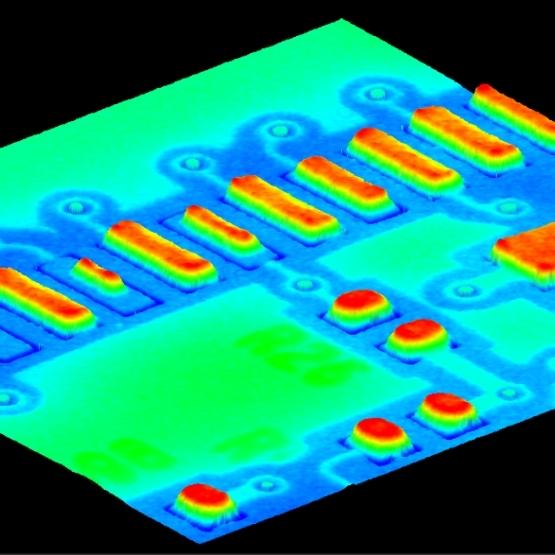

CyberOptics’ unique sensor architecture with 4 multi-view 3D sensors and a parallel projector, simultaneously captures and transmits multiple images in parallel while proprietary 3D fusing algorithms merge the images together, delivering metrology grade accuracy at production speed.

The new Dual-Mode MRS® sensor for the SE3000™ SPI system provides maximum flexibility for dedicated solder paste inspection applications, with one mode for high speed inspection and another mode for high resolution inspection.

The SPI V5 series software delivers world-class user experience with its intuitive interface, completely changing the way users interact with our system. Yet, at the same time, the software is extremely stable and simple to use enabling shortest learning curve.

Award-Winning MRS Technology

High Accuracy, Resolution and Speed

Easy-to-Use Software

Inspection Speed

MRS Sensor:

Peak: 35cm²/sec (2D + 3D)

Average: 30 cm²/sec (2D+3D)

Ultra High-Resolution MRS Sensor:

Peak: 15cm²/sec (2D + 3D)

Average: 12 cm²/sec (2D+3D)

Resolution

MRS Sensor:

18µm

Ultra High-Resolution MRS Sensor:

9µm

Board Size

SE3000: Min. 50 x 50 mm, Max. 510 x 510 mm

SE3000-X: Min. 50 x 120 mm, Max. 710 x 610 mm

SE3000-XL: Min. 50 x 120 mm, Max. 1200 x 610 mm with 2 index inspection capability

Clearance

Top (above belt): 30mm, Bottom: 35mm