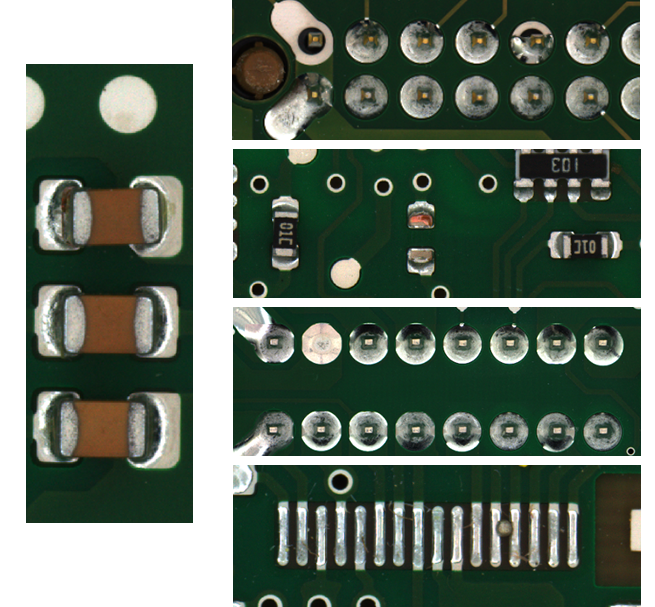

The QX600™ is designed with SIM Technology (Strobed Inspection Module) with enhanced illumination – delivering the best 01005 and solder joint inspection performance ever.

With a higher sensor resolution (12 µm), you get to see crisp, perfect quality images for more accurate defect review.

‘On-the-Fly’ High Performance

High Speed

Fast, Smart, Easy-to-use software

The SIM (Strobed Inspection Module) is at the core of every CyberOptics’ 2D AOI system. Designed and manufactured exclusively by CyberOptics, the SIM delivers high performance inspection at 200cm2/sec – And, it is absolutely calibration-free.

QX600 is equipped with SAM (Statistical Appearance Modeling) vision technology to give you the power to inspect ‘anything’ while keeping programming extremely simple – no algorithms to tune or parameters to adjust. SAM works in perfect harmony with AI² (Autonomous Image Interpretation) technology to enable fast programming and reliable discrimination against defects.

From pre-reflow inspection to post wave and post selective solder inspection, the QX250i provides crisp images for more accurate defect review.

Inspect and check for defects including coplanarity, missing pins/ components, insufficient solder, solder bridge and many more.

Inspection Speed

200cm²/sec

Board Length (without re-inspection)

QX600: Min. 50 mm (2 in.)/ Max. 400 mm† (15.7 in.)

QX600-L: Min. 50 mm (2 in.)/ Max. 470 mm†† (18.5 in.)

Board Width

QX600: Min. 50 mm (2 in.)/ Max. 308 mm (12 in.)

QX600-L: Min. 50 mm (2 in.)/ Max. 510 mm (20.0 in.)

Board Length + Width

(QX600-D Model)

Single Lane: Boarder up to 520 (L) x 510 (W) mm (20.4 x 20.0 in.)

Dual Lane: Min. 50 mm (2 in.)/ 520 (L) x 300 (W) mm (20.4 x 11.8 in.)

Component Height Clearance (max)

(QX600 and QX600-L)

Top: 35mm (1.378 in.)

Bottom: 25mm (0.984 in.)

Component Height Clearance (max)

(QX600-D)

Top: 35mm (1.378 in.)

Bottom: 35mm (1.378 in.)

Resolution

12 μm pixel size

Notes:

† With re-inspection support, the board length can be extended to 550 mm (21.6 in.) using conveyor extension kit

† † Board length can be increased to 770 mm (30.3 in.) with integrated conveyor extension. With this set up, the line length will be 1700 mm (66.9 in.)