The QX150i™ AOI system offers high value and high flexibility for all applications and is ideally suited for pre-reflow and selective solder inspection. The Strobed Inspection Module (SIM), the core engine behind QX150i™, enables on-the-fly inspection assuring a fast and smooth process.

‘On-the-Fly’, High Performance

Flexible for Various Applications

Fast, Smart, Easy-to-use software

The SIM (Strobed Inspection Module) is at the core of every CyberOptics’ 2D AOI system. Designed and manufactured exclusively by CyberOptics, the SIM delivers high performance inspection at 200cm²/sec – And, it is absolutely calibration-free.

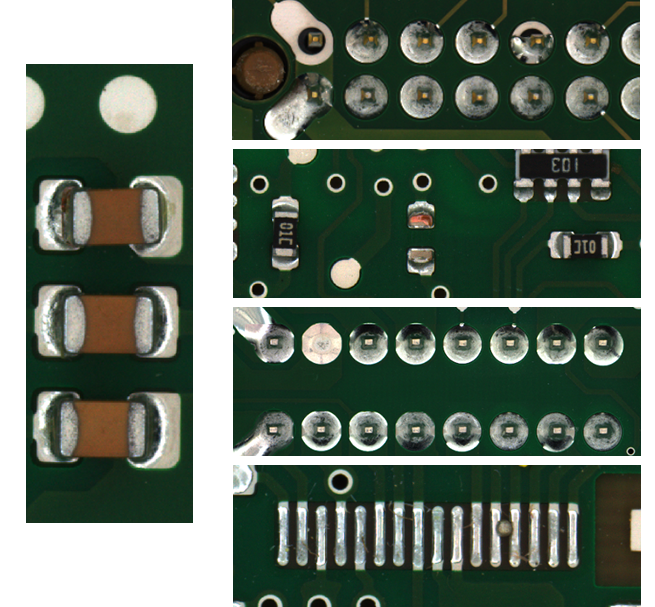

AI² (Autonomous Image Interpretation) technology on QX150i™ ensures ultrafast programming and is capable of getting you from zero to production ready in less than 13 minutes*. Powered by an 80 megapixel sensor, QX150i™ significantly improves solder joint and 01005 inspection performance. The system is also designed to provide easy wedge-in replacement of existing conveyor.

From pre-reflow inspection to post wave and post selective solder inspection, the QX150i provides crisp images for more accurate defect review.

Inspect and check for defects including coplanarity, missing pins/ components, insufficient solder, solder bridge and many more.

Board Length

Min. 50 mm (2 in.)/ Max. 400 mm (15.7 in.)

Board Width

Min. 50 mm (2 in.)/ Max. 308 mm (12 in.)

Component Height Clearance (max)

QX150i:

Top: 35 mm (1.37 in.)

Bottom: 23mm (0.90 in.)

QX150i-B:

Top: 100 mm (3.93 in.)

Bottom: 33mm (1.29 in.)

Inspection Speed

QX150i: 200cm²/sec

QX150i-B: 200cm²/sec

Imagers

80 Megapixel Sensor

Resolution

12 μm pixel size

QX100i

See QX150i brochure for additional information.

QX100i-B

See QX150i-B brochure for additional information.