The QX150™ is powered by an all-new SIM (Strobed Inspection Module) with enhanced illumination – designed to deliver true, in-line inspection performance. The SIM enables on-the-fly inspection making the QX150™ the fastest tabletop ever at 200 cm²/sec. A higher sensor resolution (12µm) offers superior quality images for more accurate defect review. In addition, as always, the SIM is calibration-free.

QX150™ also offers 100% program compatibility with all QX inline AOI systems.

‘On-the-Fly’, High Performance

High Speed Tabletop Inspection

Fast, Smart, Easy-to-use software

The SIM (Strobed Inspection Module) is at the core of every CyberOptics’ 2D AOI system. Designed and manufactured exclusively by CyberOptics, the SIM delivers high performance inspection at 200cm²/sec – And, it is absolutely calibration-free.

The QX150™ delivers quick setup and fast programming with AI² (Autonomous Image Interpretation) technology. A dramatic 90 percent reduction in examples and full support for unsupervised and semi-automatic model training means significantly lower tuning time and quality results with a single panel inspection. Perfect for those high-mix, low-volume applications.

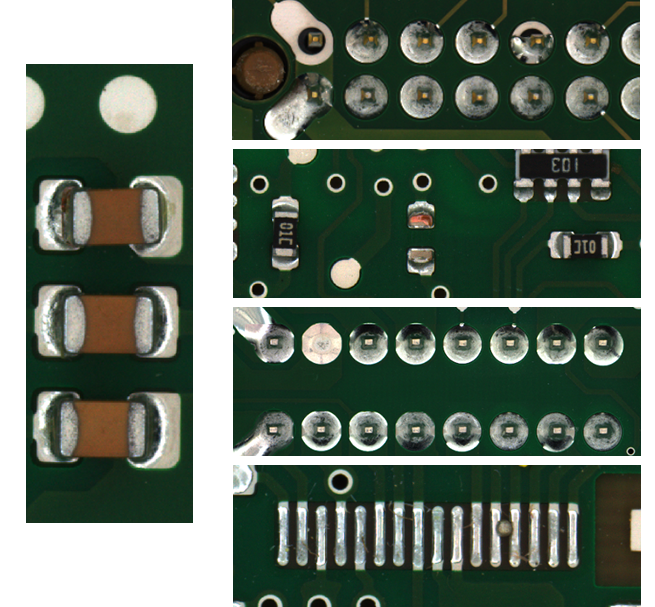

From pre-reflow inspection to post wave and post selective solder inspection, the QX150 provides crisp images for more accurate defect review.

Inspect and check for defects including coplanarity, missing pins/ components, insufficient solder, solder bridge and many more.

Board Width

QX150™

50 x 320 mm

QX150-M™

50 x 320 mm

Board Length

QX150™

50 x 330 mm

QX150-M™

50 x 510 mm

Resolution

12µm pixel size

Inspection Speed

Up to 200 cm²/sec