Phase Shift Profilometry for Wafer-Level and Advanced Semiconductor Packaging Applications

By: Tim Skunes, VP of R&D, CyberOptics Corporation (as seen on Semiconductor Digest) View Semiconductor Digest November/ December 2019 digital publication here starting on page 21

Fringe projection technology provides an unparalleled combination of speed and accuracy faster than other optical inspection technologies.

THE SEMICONDUCTOR PACKAGING industry continues to advance, with new designs adding more layers, finer features and more I/O channels to achieve faster connections, higher bandwidth and lower power consumption. As packaging technologies have evolved, manufacturers have adapted old processes and adopted new processes to connect chips to each other and to the outside world. Often these new processes use front-end like tools and techniques to perform back-end tasks, blurring the traditionally sharp distinction between the two ends of the manufacturing process. This area of overlap has been called the middle-end, and its growing importance has created an increasing need for specialized, high-precision measurement and inspection capabilities to detect defects and improve process control. CyberOptics’ NanoResolution Multi-Reflection Suppression (MRS) sensor uses phase shift profilometry and sophisticated reflection suppression technology to address these needs.

Advanced packaging

Advanced packaging techniques are evolving rapidly, and many different processes are used in different applications. In general, all seek to integrate more power and functionality in a single, smaller package having more, shorter, faster connections, within the package and to the outside world. Most use some form of vertical integration (Figure 1), stacking chips on top of each other or on specially designed substrates. Vertical connections are frequently made using bumps or pillars that extend above the surface of the chip. Because these processes use known good die, often more than one die per package, the cost of failure can be very high. The cost of failure can be even greater when the health and safety of the user is at risk, as in automotive applications for assisted or self-driving cars. Fast accurate inspection and measurement of these and other similar structures is a critical requirement for improving yields and ensuring long-term reliability.

Phase shift profilometry

Phase shift profilometry (PSP) uses structured light to measure three-dimensional (3D) objects. It projects a fringe pattern on the object and looks for shifts in the pattern that appear when surfaces at different heights are viewed from an angle to the projection direction. Figure 2 shows a schematic representation of the PSP principle and an example of a fringe pattern projected on flat surfaces of different heights. The intensity of the projected pattern varies sinusoidally across the fringes, permitting very precise measurements of relative shifts in the phase of the waveform.

pattern that appear when viewed from an angle to the projection direction. The

image on the right shows the shifts on a step standard containing surfaces at

different heights.

There are three unknowns at each pixel in such an image, phase (ϕ0), which corresponds to the height of the surface, reflectivity (R), which is measured from a uniformly illuminated video image, and modulation (m) or fringe contrast. Three or more phase shifted fringe pattern images are required to solve equation 1 for the three unknown parameters at each pixel.

Phase shift profilometry offers unparalleled speed and accuracy, with achievable data rates greater than 100 million 3D points per second and resolution scalable down to 1.5μm laterally and 25nm vertically. Importantly, for applications such as semiconductor packaging where production worthy throughput is critical, PSP can perform both 2D and 3D measurements in a single pass. It is widely used for automated 3D inspection by electronics manufacturers assembling printed circuit boards (PCB) with surface mount technologies (SMT). It is also used for solder paste inspection (SPI) by PCB manufacturers (Figure 3), and for dimensional measurements traditionally performed by coordinate measurement machines (CMM) in a variety of other industrial applications. PSP measurements are highly accurate and can be orders of magnitude faster than alternative methods.

circuit boards, surface mount technology components, and solder paste. This

system is inspecting solder paste.

However, conventional PSP measurements face significant challenges in semiconductor packaging applications. Shiny surfaces on features like solder balls can generate glints, which over-saturate the camera, or direct light completely away from the camera. Specular surfaces, such as die surfaces, create an ambiguity between the height and tilt of the surface. Multiple specular reflections between shiny surfaces can cause inaccurate height measurements. Tall, densely packed components can occlude visibility of shorter components nearby. The wide variety of features and materials, with widely ranging reflectivities, also requires special treatment in the analysis. Finally, the system must be fast enough to inspect 100% of the wafer surface

Suppressing specular reflections

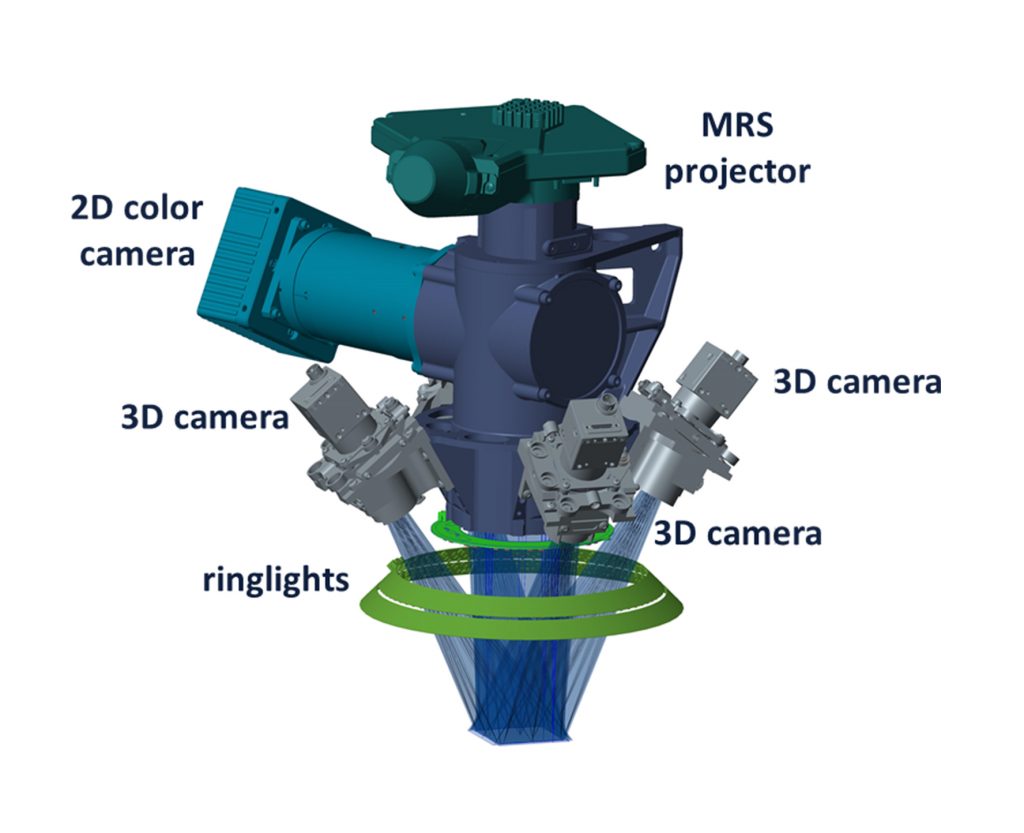

The new sensor (Figure 4) addresses the problems caused by specular reflections with a proprietary technology known as multiple reflection suppression (MRS). The sensor incorporates a single vertically positioned fringe projector, a coaxial camera for 2D measurements, and multiple cameras arranged off-axis around the projector to capture images for 3D measurements from different perspectives. The digital fringe projector can project images over a range of frequencies and orientations. The sensor uses fringe patterns of different frequencies and sophisticated “phase unwrapping” routines to achieve both fine resolution and extended range in vertical measurements. The use of a single projector and multiple cameras allows parallel data collection that greatly increases 3D measurement speed. Multiple views also ensure that none of the surface is hidden by adjacent tall features.

Multiple reflections among shiny surfaces can cause errors in PSP measurements (Figure 5). When the fringe spacing is of the same order as the physical spacing between the shiny features, the reflection can add coherently in the phase calculation. At higher fringe frequencies (more closely spaced fringes), the same reflection may reduce fringe contrast but will not affect the phase calculation (Figure 6). Typically, these spurious reflections appear differently to different cameras. The suppression technology compares information from images taken from different perspectives and at different fringe frequencies to reduce the measurement errors caused by multiple reflections.

Nanometer-scale PSP

Controlling the dimensions of critical features like bumps and pillars in current and next-generation “middle-end” processes in wafer-level and advanced packaging applications requires measurement precision, in some cases, down to the nanometer-scale. The new multi projector, multi camera sensor provides 50-nanometer height resolution and 0.5-micrometer accuracy on features as small as 25μm (Table 1). And, while retaining its ability to reject spurious multiple reflections, it adds the ability to capture and analyze specular reflections from shiny surfaces of substrates, solder balls, bumps and pillars, thus allowing accurate inspection and 3D metrology of these critical packaging features.

With data processing speeds as high as 75 million 3D points per second, it delivers production-worthy throughput of 25 wafers (300mm) per hour and more.

Predictably, as advanced packaging technology has gained traction, the size and pitch of bumps and pillars has decreased, and their number has increased (Figure 8). Bumps for the C4/Flip Chip process, now very mature, are 75μm-200μm in diameter and similarly pitched.

With the introduction of lead-free processes, size decreased somewhat to 75μm-150μm. Copper pillar processes, currently mainstream, decoupled bump height from diameter and allowed manufacturers to decrease diameters to 50μm-100μm. Next generation processes, some of which are coming on-line now, use μ-pillars with 10μm-30μm diameters.

The new sensor includes high-resolution optics with 3 μm lateral resolution, more than enough for bumps used in most current generation processes. One obstacle overcome by designers was the integration of high NA (numerical aperture) optical elements for the multiple cameras in very limited available space. In principle, the technology should be able to scale down to 1.5μm lateral resolutions.

die is increasing. The new sensor can support most current and next generation

processes.

Critical parameters to be controlled in bump and pillar processes include

bump height, position, diameter, shape, and coplanarity (Figure 9). All are critical to ensure reliable connections. Reliability is an area of special concern for advanced packaging processes. Inter-chip connections have proven to be prone to field failures as the effects of thermal stress on disparate materials accumulate over time. Field failures are very costly for many reasons. They entail the return of finished devices containing costly known good die. They impact the reputation of the supplier with the customer. In some applications, they expose the user to health and safety risks and the device manufacturer to potential financial liability.

Many device users, especially in higher risk markets like automotive applications, are requiring 100% inspections. Other optical inspection technologies are challenged to provide 100% inspection with sufficient accuracy and precision at production throughputs, and often use a sampling strategy, extrapolating measurements of a subset of features to characterize the whole population. Many also require separate passes for 2D and 3D measurements. The new sensor’s high speed and ability make both 2D and 3D measurements in a single pass allow it to deliver accurate, repeatable results from a single pass at throughputs in excess of 25 wafers (300mm) per hour.

Using Specular Reflections

Bumps and pillars typically have shiny, mirror-like surfaces. Many substrate materials also return specular reflections. As described above, the new sensor is designed to suppress errors caused by spurious multiple reflections from specular surfaces. The multi projector, multi camera architecture also enables an additional channel designed specifically to measure specular surfaces. Conventional fringe projection cannot measure these surfaces because it relies on variations in the intensity of a diffuse reflection, which is not available. However, if the specular surface is treated as an optical element, distortions in the reflected pattern can be used to calculate the geometry of the surface (Figure 10).

Conclusion

Fringe projection technology provides an unparalleled combination of speed and accuracy faster than other optical inspection technologies. Solutions are available to suppress errors caused by spurious multiple reflections from shiny components. The new multi camera, multi projector sensor architecture includes a separate measurement channel specifically designed to use information contained in specular reflections to characterize shiny surfaces like those found on solder bumps and pillars. It offers 3μm lateral resolution and 50nm vertical resolution, and can ultimately scale 1.5μm lateral resolution and 25nm vertical resolution. The sensor can perform both 2D and 3D measurements in a single pass and is 2-3X faster than alternate technologies. With data acquisition rates up to 75 million 3D data points per second, it can perform 100% inspection on 300mm wafers at a throughput of 25 wafer per hour.

Back

Back

Back to News

Back to News