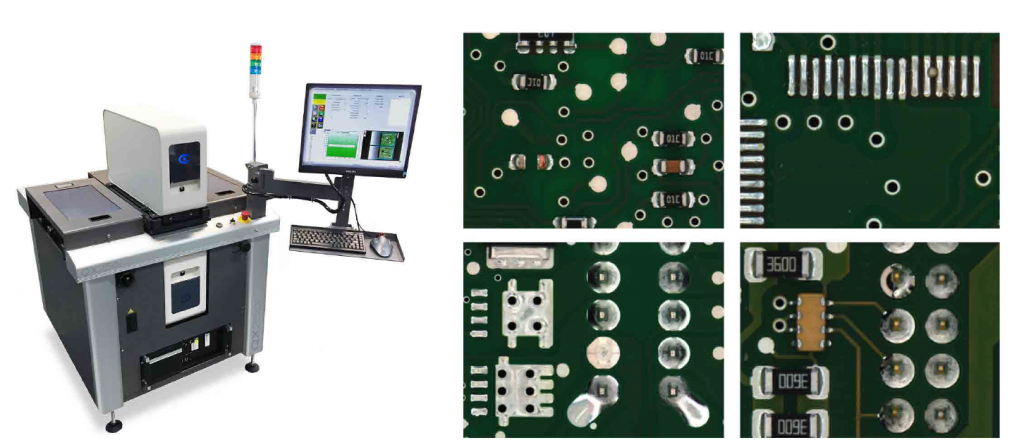

Microart Services Selects QX250i™ 2D AOI System for Diverse Inspection Needs

Microart Services Inc., founded in 1981, is an industry-leading electronic contract manufacturing company. Microart utilizes high-speed automation and advanced equipment to deliver high-mix, high-complexity assembly solutions to its diverse customer base.

Challenge

Microart needed an automated solution for post-solder inspection on a variety of boards with a range of applications. Microart’s rapidly growing business demanded an increasing supply of highly skilled labor, but the breadth and diversity of their services made locating talent with the requisite training a challenge. As a result, Microart sought a technological replacement which could provide advanced inspection capabilities in order to continue delivering high-quality products to their customers.

Solution

After a comparative analysis of CyberOptics’ and competitors’ products, Microart deemed the CyberOptics QX250i 2D AOI system was best-suited for their needs. The sensor technology of the QX250i provides fast, high-resolution inspection for all applications—pre-reflow, post-selective solder, and post-reflow inspection—delivering clear images for accurate defect review. The QX250i has exceeded expectations regarding accuracy and resolution and has allowed Microart to utilize data they had previously never been able to gather.

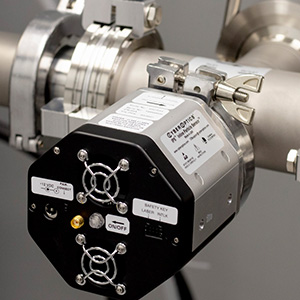

Central to the QX250i AOI systems are dual top and bottom mounted SIMs (Strobed Inspection Module), a sensor technology designed and manufactured exclusively by CyberOptics. The SIM delivers fast performance at 110cm²/sec and requires no manual adjustment. This highly accurate automated system has greatly increased the efficacy and speed of Microart’s inspection processes, allowing them to ramp up the rate of inspection by a factor of 2-3x.

The QX software utilizes AI² (Autonomous Image Interpretation) technology, designed for low volume – high mix, and high volume – low mix applications. Programming is faster and simpler – with a 90% reduction in examples required to create a complete production ready program that helps achieve superior defect detection and low false call rates with just one example. Microart has found the QX250i with QX software to be extremely straightforward to install and use and plans to invest in more QX250i systems in the near future. In addition to its ease-of-use and impressive accuracy and speeds, the QX250i provides Microart the overarching benefit of a heightened quality guarantee to its customers.

Benefit Summary

Microart considers the QX250i 2D AOI system a superior product among its competition. The high resolution, high accuracy and speed of the QX250i sensing technologies satisfy Microart’s diverse and quickly scaling production needs.

About Microart Services

Established in 1981, Microart Services, Inc., is a full-service electronic manufacturing and design services company servicing the North American and European markets from the greater Toronto area. Microart serves 300 customers a month on average and completes 1000 unique jobs per month. The company provides circuit design, PCB layout, bare board manufacturing, PCB assembly testing and box build, and supply chain services. Their customers come from a wide variety of industries, including as medical, marine, military, robotics, consumer goods, and telecom, among others. Discover more at microartservices.com

Back

Back

Back to News

Back to News