CyberOptics Features Inspection and Metrology Systems Powered by MRS™ Sensor Technology at Productronica 2021

For Advanced SMT and Semiconductor Applications

Customers worldwide are improving their yields and processes with CyberOptics’ systems that are powered by MRS sensor technology. The SQ3000+ Multi-Function system for inspection and metrology is an extension of the multi-award-winning SQ3000 platform deemed best-in-class, that not only conducts AOI and SPI, but uniquely delivers in-line, full coordinate measurement (CMM) data in seconds, not hours.

The new SQ3000+ offers a combination of unmatched high accuracy and high speed, with an even higher resolution MRS sensor that inhibits reflection-based distortions caused by shiny components and surfaces. This all-in-one system is specifically designed for high-end applications including advanced packaging, mini-LED, advanced SMT for medical, military, aerospace and advanced electronics, 008004/0201 SPI, socket metrology and other challenging CMM applications.

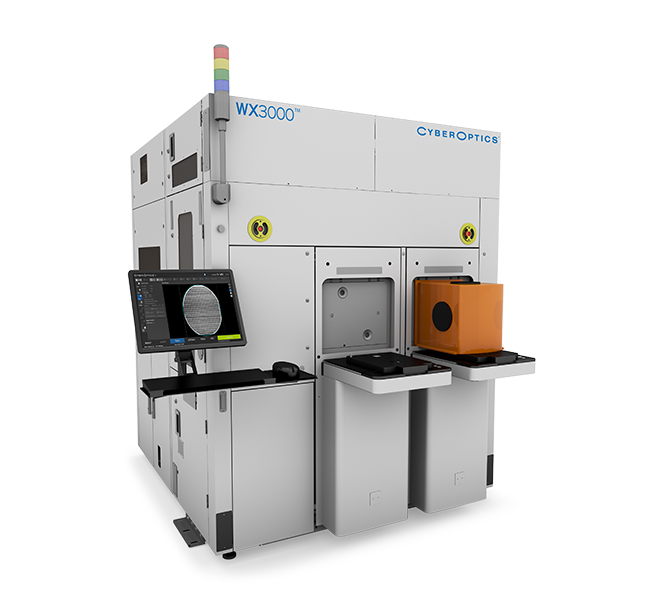

For wafer-level and advanced packaging, the WX3000 Metrology and Inspection system provides sub-micrometer accuracy on features as small as 25µm. The NanoResolution MRS sensor rejects spurious multiple reflections from shiny and specular surfaces of solder balls, bumps and copper pillars, enabling highly accurate metrology and inspection of these critical packaging features. Fast, complete 100% 3D/2D inspection and metrology can be conducted with throughput greater than 25 wafers (300mm) per hour, at speeds 2-3X faster than alternative solutions.

Back

Back

Back to News

Back to News