Case Study – Multi-Part Scanning and Inspection with CyberGage360

CyberGage®360 Scanning and Inspection Capabilities for Batch Parts

Benefit Summary

CyberGage360 provides the ability to automate 3D scanning and inspection of a batch of small parts in one scan cycle, significantly increasing throughput, and decreasing part handling and labor.

Challenge

Our customer needed to upgrade their inspection process to inspect 500-1000 parts per day. The existing manual process was costly and time consuming. Manual inspection of individual parts proved ineffective as defects were not always detected by operators.

Our customer needed a robust, flexible, and automated solution to get reliable 3D scan data and inspect their parts in batches, in order to meet the 500-1000 per day goal.

Solution

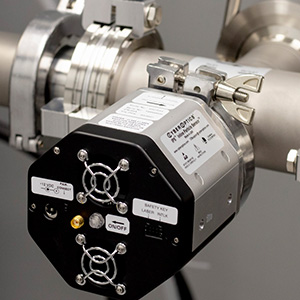

CyberGage360 is a versatile solution that is easy to use and provides consistent, accurate results at high speeds. The Multi- Reflection Suppression (MRS) sensor, software and system all work together to completely automate the scanning and inspection process, streamlining the ability to gain pass/ fail information for one or more parts.

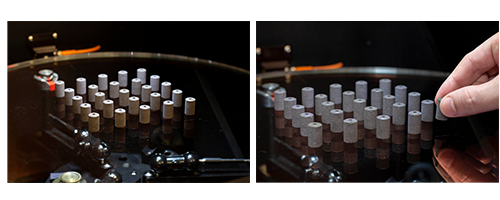

The CyberGage360 generates a highly precise full 360° volumetric 3D scan very quickly of parts being placed on the optically clear glass plate, eliminating any fixtures. A batch of parts, 25 for this example can be scanned and inspected together when placed on the glass plate by hand in an approximate grid.

When the scan initiates, the parts are scanned from above and below without flipping or manually moving the parts. For this application, the glass plate is programmed to rotate and scan in 8 positions, which takes 4 minutes. The net scan time per part is less than 10 seconds.

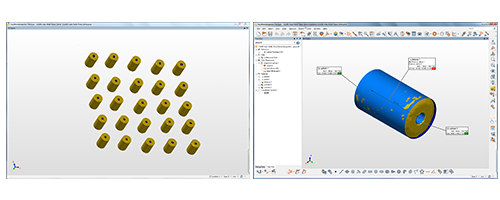

Once the scan is complete, 3D data from each part is individually compared to the nominal CAD model providing both form and dimensional analysis.

When the inspection is complete, the Pass/ Fail information for the parts is presented to the operator visually and results are stored for SPC analysis. The overall time from start of the scan to availability of final Pass/ Fail information takes 6-7 minutes.

The parts are unloaded and then sorted appropriately, and the process repeats for the remaining samples. Up to 150 parts can be fully inspected in 1 hour, 1000 parts can be inspected in a single 8 hour shift

Back

Back

Back to News

Back to News