Climate Change, Manufacturing Tolerances or Design Changes

What caused so many more home runs in Professional Baseball this year?

CyberOptics will not be able to help you learn how Climate Change affected the home run statistics this year, but utilizing 3D Industrial CT Scanning could help identify changes in baseball design and manufacturing which may have contributed to a record spike in home runs experienced in the 2019 regular season.

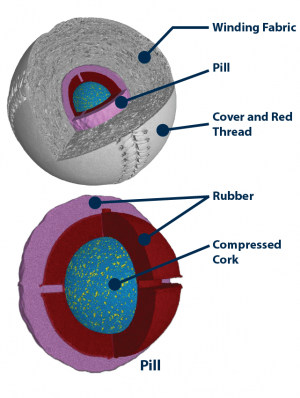

Using X-Ray Industrial Computed Tomography, a high resolution, metrology-grade, non-destructive 3D measuring system, CyberOptics provides its customers with Turnkey 3D Scanning Systems and 3D Scanning Services to measure more than just the surface geometry of an object. By capturing many X-Ray images of an object from multiple directions, Industrial CT can be used to measure objects in full 3D to give access to internal and external surface geometry along with material structure information. Additionally, multi-part assemblies can be visualized without destroying the part or changing the shape of the assembly or components.

Capabilities

X-Ray CT has become one of the most powerful industrial forensic

tools available on the market today, allowing advanced visualization

and analysis options that have never been available to this level

previously.

With this non-destructive tool, users can now see inside a part to identify different materials, shown in the baseball example, along with verifying assembly details and performing root cause analysis without removing critical constraints on the part.

Additionally, the 3D scan data of the external and internal surface geometry of the measured object can be aligned with the nominal 3D CAD geometry giving the ability to perform high-level quality and inspection functions.

In a similar fashion, the 3D scan data of two different parts can be compared to show the true differences between Part A and Part B which is useful in cavity verification and supplier comparison processes.

With this information, dimensional metrology and defect detection tools are available including form analysis, coordinate measurement, GD&T, wall thickness analysis, porosity and inclusion analysis, fiber composite material analysis and finite element analysis. This multi-functional data set, available through the computed tomography acquisition process, can also be used for reverse engineering parts where digital 3D CAD geometry is not already available. Industrial CT Scanning makes all of these capabilities available through a single data set.

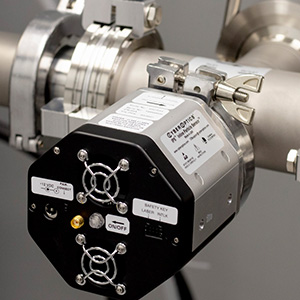

Industrial CT Scanning Systems

CyberOptics Industrial Metrology offers the EasyTom S and EasyTom CT Scanners by RX Solutions for high flexibility 3D Industrial CT scanning in a variety of applications and for a wide range of part sizes. These easy to use and maintenance free systems come with the ability to efficiently and reliably measure objects made from materials such as plastics, ceramics, composites, aluminum, iron and steel. Our team will verify your requirements and recommend the best solution including the right CT scanner and analysis software tools to successfully perform your inspection, visual analysis or reverse engineering applications.

Back

Back

Back to News

Back to News